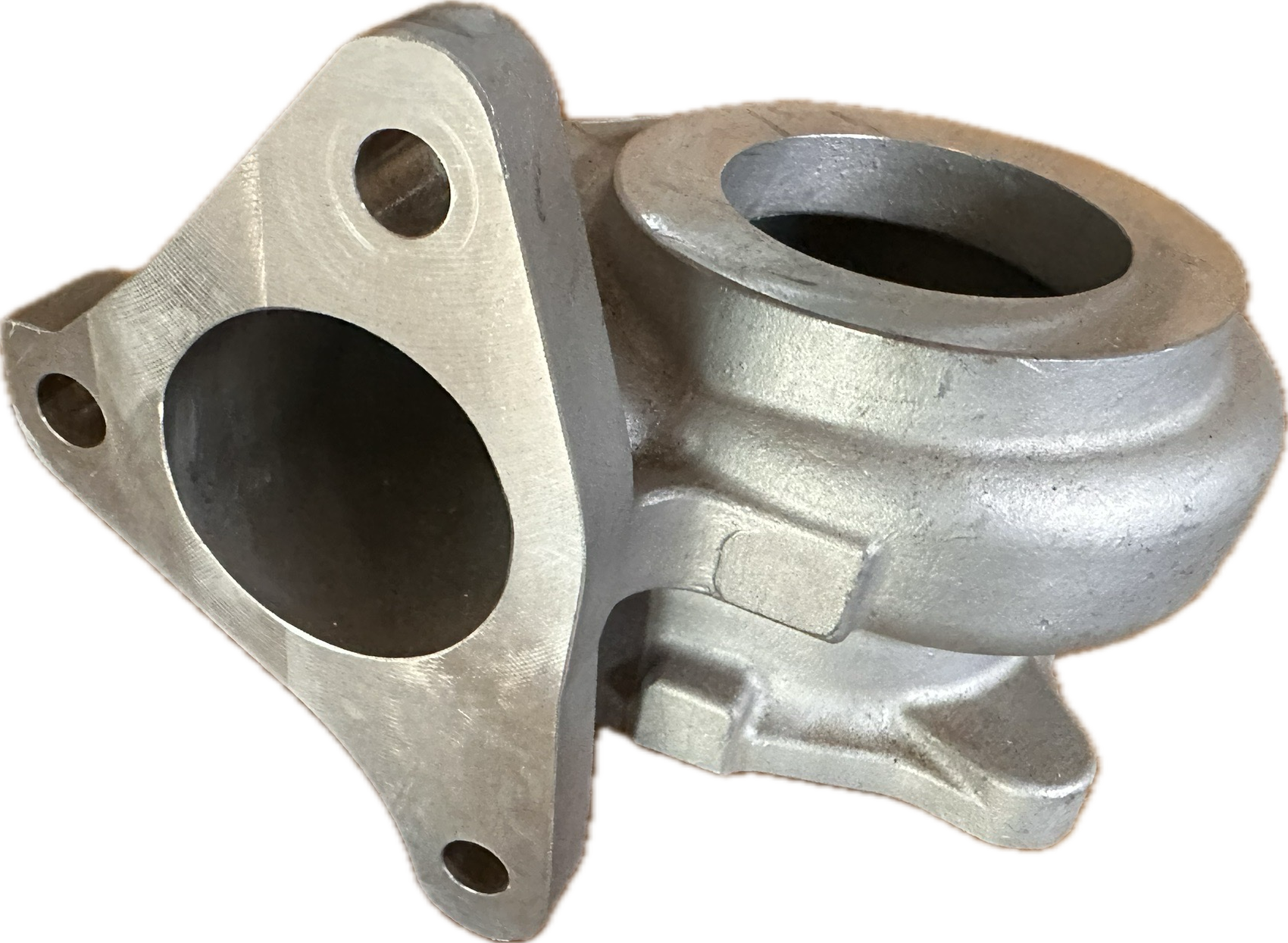

Our Investing Casting supplier process ensures high-quality components tailored to your specifications. Using advanced techniques like 3D printing and prototype development, we deliver precise parts for automotive, solar cars, and bicycles. The investment casting method provides excellent dimensional accuracy, which is crucial for complex geometries like door hinges, locks, and pins.

In our Investment Casting parts and parts stamping, we employ cutting-edge stamping technologies to produce components with exceptional strength and durability. This process is ideal for high-volume production, ensuring consistency across large batches. Our customized approach allows us to meet the exact needs of automotive and mechanical applications.

For precision Investment Casting, we specialize in delivering high-precision components with tight tolerances, essential for critical assemblies like bearings and bushings. Our focus on precision ensures that every part fits perfectly within your systems, reducing wear and tear, and extending the lifespan of your products. Please feel free to contact us.

Application:

- Versatility in Manufacturing: We utilize a wide range of processes including investing casting, prototype development, 3D printing, and stamping. This versatility allows us to produce complex components like door hinges, locks, and pins with precision and efficiency.

- Customization and Flexibility: Our OEM and customized services cater to specific customer needs, ensuring that every component, whether for automotive, solar cars, or bicycles, meets exact specifications.

- Advanced Technology Integration: By integrating modern technologies such as 3D printing and precise stamping, we ensure that our products maintain high-quality standards from prototype through to mass production.

- Cost-Effective Solutions: We offer competitive pricing without compromising on quality, making us a preferred partner for clients seeking cost-effective solutions in mechanical component manufacturing.

- Comprehensive Engineering Support: Our engineering support extends from the initial design phase through to final production, ensuring that every aspect of the manufacturing process is optimized for quality and efficiency.