Multiserve Technology Co., Ltd provides premium PCBA Automatic Conformal Coating and Electronic Epoxy Potting Services, ensuring rapid turnarounds for prototypes and low to medium-scale production. Our solutions are designed to boost the reliability and lifespan of electronic assemblies, offering robust protection against environmental hazards. Our conformal coating services apply a protective chemical layer that conforms to circuit board topologies, safeguarding electronic circuits from moisture, chemicals, and other contaminants. With our advanced conformal coating application line, we guarantee precise control and consistent quality, enhancing product reliability and production efficiency. We offer diverse application methods, including dipping, spraying, and brushing, tailored to meet specific product requirements. The following are the advantages of our services:

Multiserve Tech's Automatic Conformal Coating and Potting Service Advantages:

➥ Electronic Potting and Encapsulation:

Our electronic potting process involves filling assemblies with solid or gelatinous compounds, providing resistance to shock, vibration, and environmental contaminants. This method offers additional shielding, heat dissipation, and a tamper-proof solution. We support a variety of potting compounds, including hard tamper-proof, silicone encapsulants, and flexible apparent transparent epoxy compounds.

➥ Protection Against Harsh Environments:

Our conformal coatings safeguard PCBAs against chemicals, corrosive agents, and moisture, ensuring long-term durability.

➥ Minimized Environmental Stress:

Conformal coatings reduce environmental stress on PCBAs, enhancing their performance and reliability.

➥ Insulating Properties:

These coatings allow reduced PCB conductor spacing, optimizing space and design flexibility.

➥ High Flexibility:

Coatings offer easy removal, repair, and replacement, ensuring maintenance and adaptability.

➥ Supported Materials:

Our services utilize a range of high-quality materials, including Humiseal 1B31, 1B73, and 1A33; 3M Novec; ACC Silicones ACC15; Trinity Shields PC101-18; Peters Coating; HYSOL PC20M; ELANTAS CE1170; HPA; and Surclean PCC1704, ensuring superior protection and reliability for your electronic assemblies.

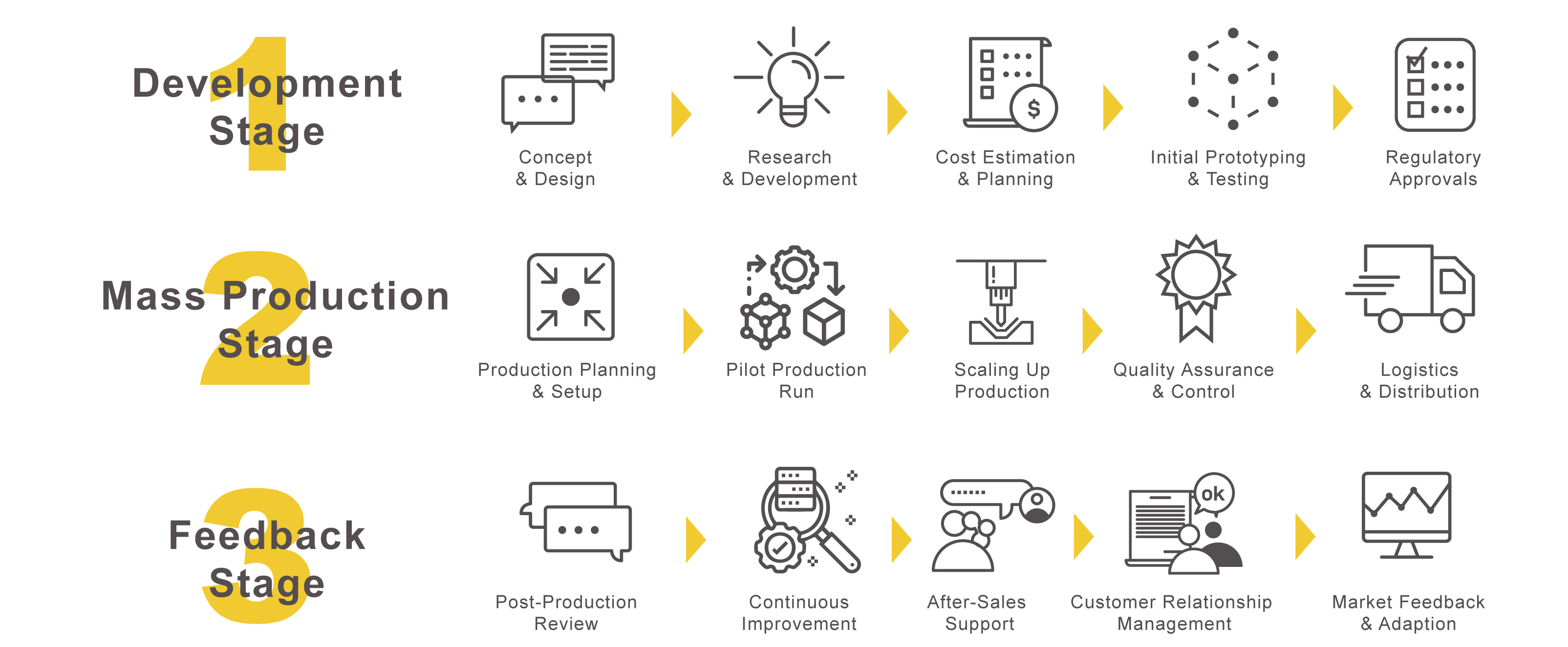

Service Process

About Us

Established in 1990, Multiserve Technology Co., Ltd. (MST) is revolutionizing the Electronics Manufacturing Services (EMS) industry. Our comprehensive manufacturing capabilities, including SMT, DIP (PTH), conformal coating, and system assembly, combined with our expertise in procuring active/passive components and mechanical parts, position us as the premier one-stop manufacturing solution.

At MST, our customer-centric approach ensures clear communication, flexibility, and responsiveness at every project phase, keeping our clients informed and satisfied. We provide cost-effective solutions without compromising quality by leveraging efficient supply chain management and optimized processes to deliver top-notch products.

Our engineering team collaborates closely with clients to develop innovative solutions, ensuring a competitive edge and market leadership. From PCB assembly to full-system integration, we uphold rigorous quality standards in all aspects of production. Utilizing state-of-the-art technologies, our advanced and automatic conformal coating production lines ensure efficient production and thorough testing, minimizing lead times while maintaining superior product standards.

With a global presence spanning North America, Europe, Australia, Africa, and Asia, we swiftly adapt to regional requirements and market dynamics, providing localized support and unparalleled flexibility. Partner with MST and experience the advantages of working with a trusted industry leader committed to excellence, innovation, and success.