At Multiserve Technology Co., Ltd, we specialize in producing high-quality PCB assemblies for medical devices and diagnostic equipment. We focus on precision and compliance to meet stringent regulatory requirements. We use high-reliability materials suitable for medical environments, and our robust testing procedures guarantee long-term reliability and durability, even under harsh conditions. We employ advanced manufacturing techniques for high precision and tight tolerances, implementing fine-pitch components and microelectronics to ensure the functionality and performance of medical devices. We serve PCB Assembly and System Assembly for healthcare product ranges like diagnostic equipment, monitoring devices, therapeutic devices, blood glucose meters, etc.

With solid relationships with reputable suppliers, efficient supply chain management, and the ability to scale production volumes, we ensure timely delivery and flexibility to accommodate design and production requirements. Our state-of-the-art facilities handle complex assemblies, providing a one-stop solution for Medical Device PCBA Production. The following are the advantages of our services.

Multiserve Tech's Medical Devices PCBA Production Advantages:

➥ Customization and Innovation :

॰ Collaboration with medical device companies on innovative solutions and cutting-edge technologies.

॰ Customization capabilities to meet specific design and functional requirements. Rapid prototyping and iterative development to support medical device innovation and time-to-market.

➥ Scalability and Flexibility:

॰ Ability to scale production volumes from prototypes to high-volume manufacturing.

॰ Flexibility to accommodate changes in design and production requirements.

➥ Precision and Accuracy:

॰ Advanced manufacturing techniques to achieve high precision and tight tolerances.

॰ Implementation of fine-pitch components, microelectronics, and advanced interconnect technologies.

॰ High level of precision in assembly to ensure functionality and performance of the final medical device.

➥ Quality and Reliability:

॰ Adherence to international standards: ISO 13485, ISO 9001 and ISO 14001.

॰ Compliance and Certifications: Compliance with environmental and safety regulations such as REACH, RoHS (Restriction of Hazardous Substances), and Conflict Minerals survey. Certifications related to automotive safety and performance standards.

॰ Rigorous quality control processes, including 100% inspection and traceability of components. Use of high-reliability components and materials suitable for medical environments.

➥ Advanced Manufacturing Capabilities:

॰ State-of-the-art facilities equipped with advanced machinery for SMT, through-hole, and mixed technology assembly.

॰ Capability to handle complex and miniaturized assemblies

➥ Supply Chain Management:

॰ Strong relationships with reputable suppliers of medical-grade components and materials.

॰ Efficient supply chain management to ensure timely delivery and minimize production delays. Strategies to manage component obsolescence and ensure continuity of supply.

Choose Multiserve Technology Co., Ltd for reliable, customized PCBA solutions for medical devices and elevate your products to the next level. Contact us today to learn more.

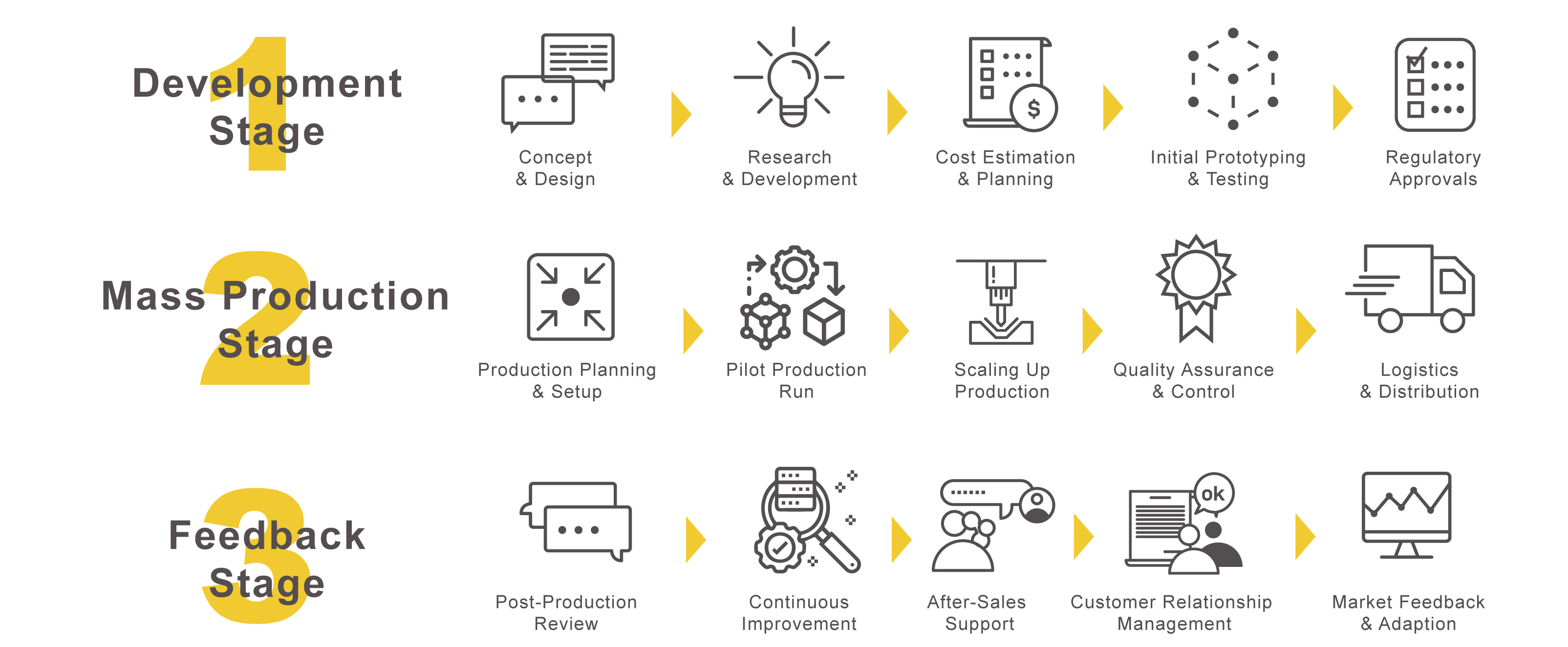

Service Process

About Us

Established in 1990, Multiserve Technology Co., Ltd. (MST) is revolutionizing the Electronics Manufacturing Services (EMS) industry. Our comprehensive manufacturing capabilities, including SMT, DIP (PTH), conformal coating, and system assembly, combined with our expertise in procuring active/passive components and mechanical parts, position us as the premier one-stop manufacturing solution.

At MST, our customer-centric approach ensures clear communication, flexibility, and responsiveness at every project phase, keeping our clients informed and satisfied. We provide cost-effective solutions without compromising quality by leveraging efficient supply chain management and optimized processes to deliver top-notch products.

Our engineering team collaborates closely with clients to develop innovative solutions, ensuring a competitive edge and market leadership. From PCB assembly to full-system integration, we uphold rigorous quality standards in all aspects of production. Utilizing state-of-the-art technologies, our advanced and automatic conformal coating production lines ensure efficient production and thorough testing, minimizing lead times while maintaining superior product standards.

With a global presence spanning North America, Europe, Australia, Africa, and Asia, we swiftly adapt to regional requirements and market dynamics, providing localized support and unparalleled flexibility. Partner with MST and experience the advantages of working with a trusted industry leader committed to excellence, innovation, and success.