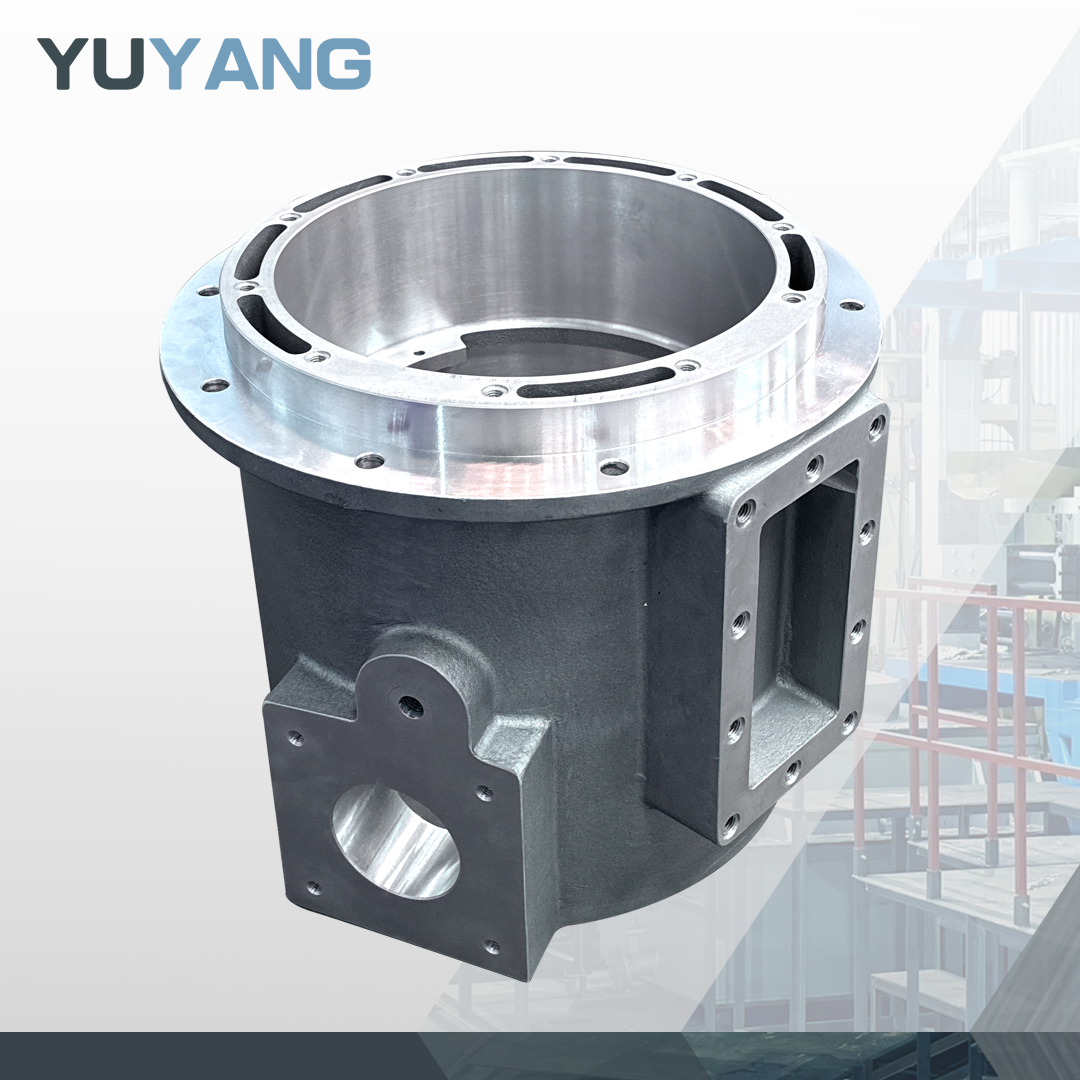

Factory of Aluminum Casting Air Conditioning Equipment

PID:

2734423

Model No:

0

Made in:

Taiwan

Quantity:

1000 Piece(s)Available

-

+

Payment:

Send Inquiry

Supplier Details

Yuyang Investment Co., Ltd.

Member Since

109

Address

4F., No. 308, Sec. 2, Zhongshan Rd., Bali Dist., New Taipei City

Contact Seller

View company information >

Key Features

As a factory of aluminum casting air conditioning equipment, we specialize in producing high-quality components designed to meet the demands of the air conditioning industry. Our advanced low-pressure casting technology ensures precision and reliability in every piece, making us as a trusted partner in cooling motor housings and compressor end covers. By selecting aluminum as our primary material, we are committed to producing lightweight yet structurally strong products. This focus on material excellence not only enhances the performance and durability of our air conditioning equipment but also aligns with the industry's move towards more efficient and sustainable solutions. Feel free to contact us at any time.

Features

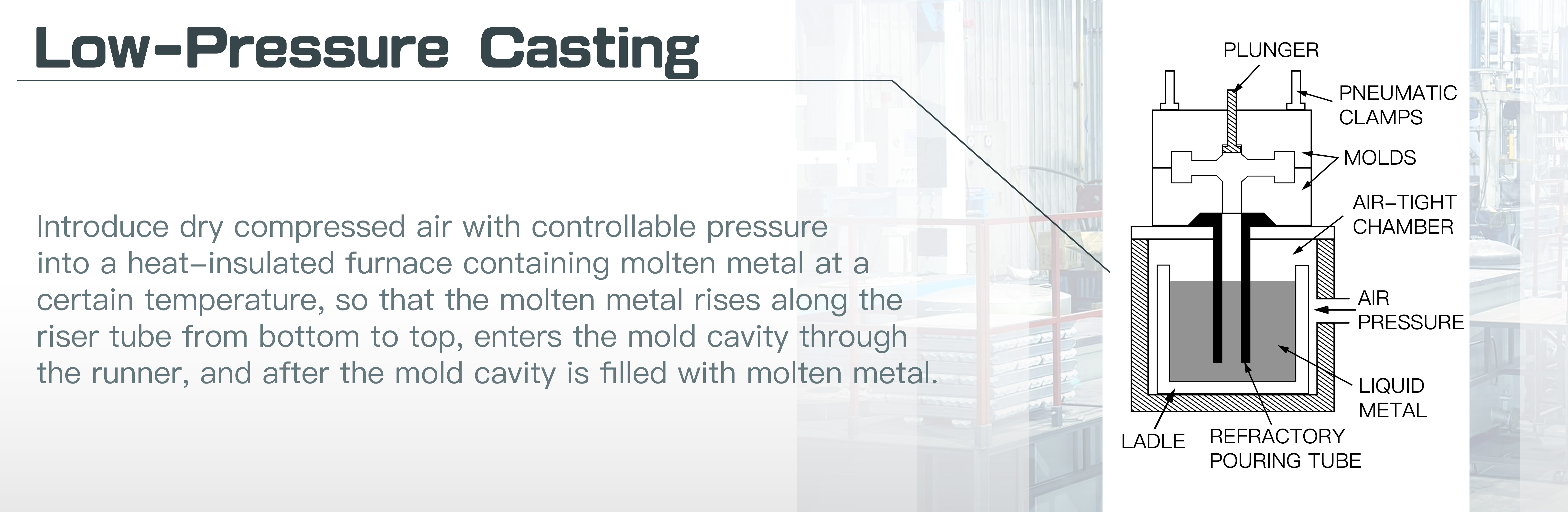

- Low-pressure casting

- Air conditioning equipment industry, cooling motor housings and compressor end covers

- To pursue the lightweight and structural strength of the finished product, aluminum material is selected for manufacturing

- The principle of low-pressure casting involves introducing pressure-controlled dry compressed air onto the surface of the molten metal in an insulated furnace. This causes the molten metal to rise through the riser tube from the bottom to the top and enter the mold cavity via a bypass. Once the molten metal fills the mold cavity, the air pressure is increased and maintained until the casting is completely solidified. The pressure is then released, allowing the unsolidified molten metal in the riser tube and bypass to flow back into the insulated furnace. This completes one casting process, and the desired casting is obtained after the mold is opened.

Spec.

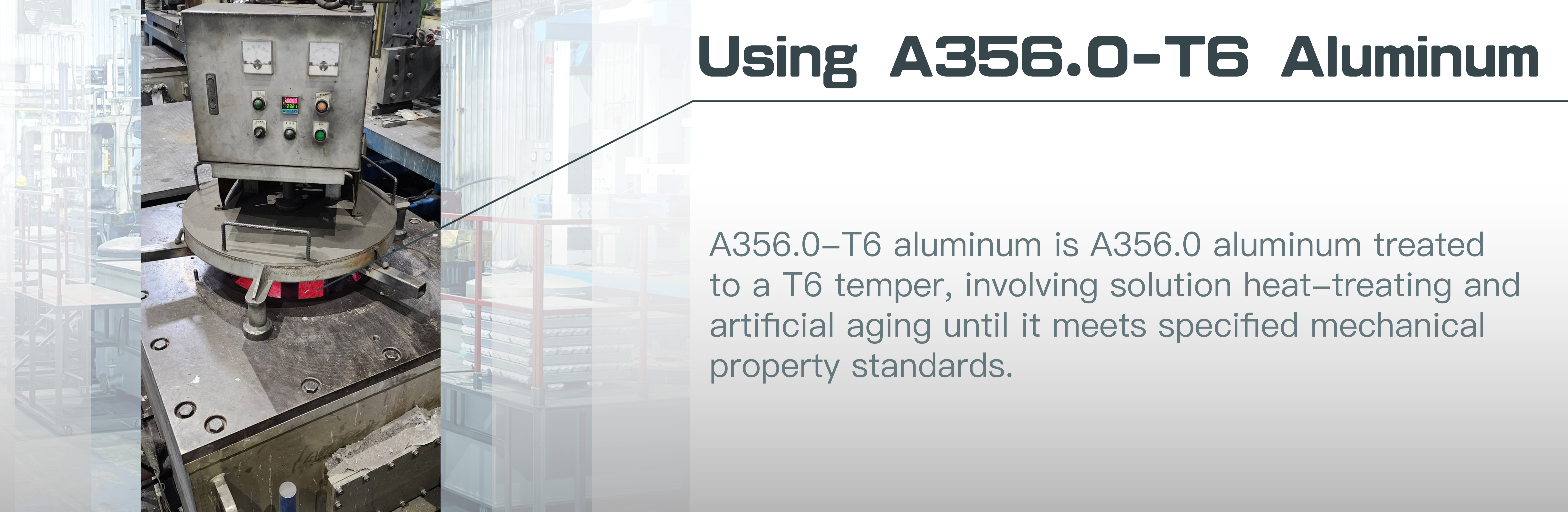

- Material: A356.0-T6

- Weight: 22.6 kgs

As a factory specializing in aluminum casting for air conditioning equipment, we take pride in our advanced low-pressure casting techniques. Our focus lies in the air conditioning equipment industry, particularly in cooling motor housings and compressor end covers. To ensure the lightweight yet structurally strong nature of our finished products, we use aluminum as our primary material, specifically A356.0-T6 aluminum.

A356.0-T6 aluminum is A356.0 aluminum in the T6 temper. To achieve this temper, the metal is solution heat treatment and artificial aging until it meets the standard mechanical property requirements. Our cooling motor housings are made from A356.0-T6 aluminum after the heat treatment process, weighing approximately 22.6 kilograms. Similarly, our compressor end covers are also made from A356.0-T6 aluminum after heat treatment, with a weight of around 36.7 kilograms. These specifications highlight our commitment to using top-quality materials and processes in the manufacturing of our products.

Our low-pressure casting process is precise and efficient. It involves the use of pressure-controlled, dry compressed air on the surface of molten metal in an insulated furnace. This process allows the molten metal to rise through a riser tube and enter the mold cavity through a bypass. Once the mold cavity is filled, the air pressure is increased and maintained until the casting solidifies. The pressure is released, enabling any remaining molten metal to flow back into the furnace. This meticulous process ensures the creation of high-quality castings with minimal defects.

One of the key advantages of low-pressure casting is its ability to produce complex shapes with thin walls, making it ideal for applications in the air conditioning equipment industry where lightweight and intricate designs are often required. Additionally, low-pressure casting helps reduce porosity in the final product, improving its mechanical properties and overall quality.

In addition to our manufacturing capabilities, we also place a strong emphasis on quality control and customer satisfaction. Our team of experienced professionals ensures that each product meets the highest standards before it leaves our facility. We take pride in providing reliable and efficient air conditioning equipment components that meet the needs of our customers.

Furthermore, we are constantly innovating and improving our processes to stay ahead in the industry. We invest in research and development to develop new casting techniques and improve the performance of our products. Our goal is to continue delivering high-quality air conditioning equipment components that exceed our customers' expectations.

Our products in different indstries | Products and Services | |||||

FC/FCD casting | Alumimum alloy casting | Welding | Precision machining | Surface treatment | Assembling | |

Automobile Industry | ● | ● | ||||

Aeospace Industry | ● | |||||

Energy Equipment Industry | ● | ● | ● | ● | ● | ● |

Power Transmission Industry | ● | ● | ● | ● | ● | |

Machinery Equipment Industry | ● | ● | ● | ● | ● | ● |

Air Conditioning Equipment Industry | ● | ● | ● | ● | ● | |

Medical Equipment Industry | ● | ● | ||||

Electronics Components Industry | ● | ● | ● | ● | ● | |

Automation and Robotics Industry | ● | ● | ● | |||

Aluminum Casting Facility | ||||||

Brand | Type | Aquire Date | SN / Spec. | Process Capability | Appliance | Production Line Configuration |

Toyosaki | Resin Sand Recycling Equipment | 2010/10 | UDC-89PR | 5T/Hr | Furan Resin | Sand Mold Line - Molding |

Toyosaki | Resin Sand Mixing Equipment | 2010/10 | Customized | 10T/Hr | Furan Resin | Sand Mold Line - Molding |

Toyosaki | Resin Sand Mixing Equipment | 2010/10 | Customized | 3T/Hr | Furan Resin | Sand Mold Line - Molding |

Jnhaomai | Low Pressure Casting Equipment | 2011/03 | JZ455-500 | 500Kg | Aluminum | Sand Mold / Metal Mold Hybrid Line - Casting |

Jet-Shine | Low Pressure Casting Equipment | 2015/03 | JZ455-300 | 300Kg | Aluminum | Metal Mold Line - Casting |

Jet-Shine | Low Pressure Casting Equipment | 2017/8 | Customized | 300Kg | Aluminum | Metal Mold Line - Casting |

Jet-Shine | Low Pressure Casting Equipment | 2018/3 | Customized | 300Kg | Aluminum | Metal Mold Line - Casting |

Jet-Shine | Low Pressure Casting Equipment | 2022/12 | Customized | 700Kg | Aluminum | Sand Mold / Metal Mold Hybrid Line - Casting |

Jet-Shine | Low Pressure Casting Equipment | 2022/12 | Customized | 700Kg | Aluminum | Sand Mold / Metal Mold Hybrid Line - Casting |

Jnhaomai | Mobile Degassing Equipment | 2011/03 | Customized | ─ | Aluminum | Sand Mold Line - Smelting |

Kanghao | Hanging Degassing Equipment | 2017/05 | Customized | ─ | Aluminum |

This is a notification message!

|