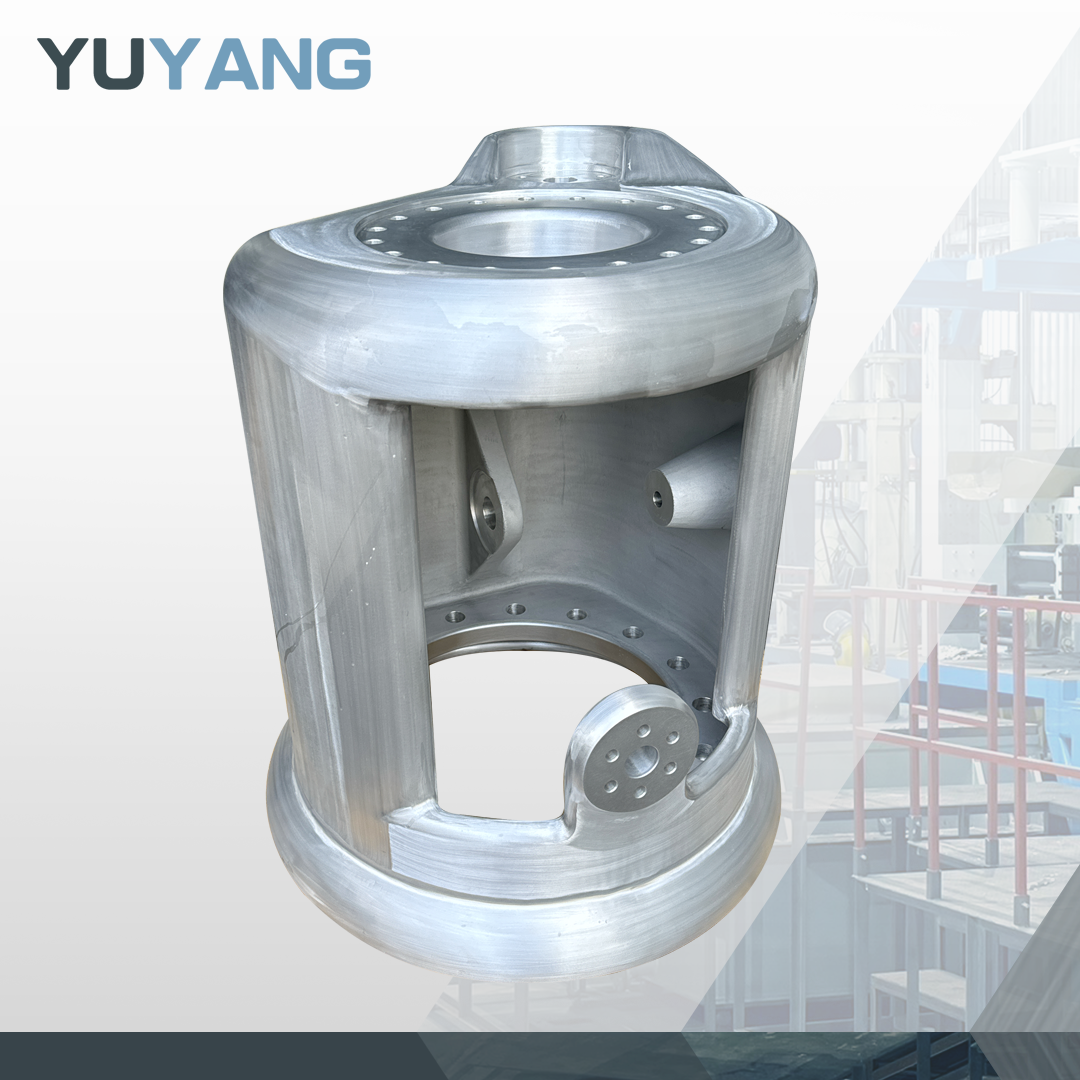

Factory of Aluminum Casting for Arc Extinction Products

PID:

2734415

Model No:

0

Made in:

Taiwan

Quantity:

1000 Piece(s)Available

-

+

Payment:

Send Inquiry

Supplier Details

Yuyang Investment Co., Ltd.

Member Since

109

Address

4F., No. 308, Sec. 2, Zhongshan Rd., Bali Dist., New Taipei City

Contact Seller

View company information >

Key Features

As a manufacturer of aluminum castings specializing in fixed-side arc extinguishing barrels for the power distribution equipment industry, we offer top-quality products crafted through low-pressure casting techniques. Our commitment to excellence is evident in every aspect of our manufacturing process. Our fixed-side arc extinguishing barrels are designed to meet the highest standards of safety and efficiency. We understand the importance of lightweight finished products without compromising on mechanical strength, which is why we exclusively use aluminum for production. This ensures that our products are not only durable and reliable but also lightweight and easy to handle. We take pride in our meticulous attention to detail and our dedication to providing products that exceed customer expectations. Please don't hesitate to contact us.

Features

- Low-pressure casting

- Movable side arc extinguishing barrel for the power distribution equipment industry

- Aluminum is selected for manufacturing to pursue lightweight finished products and structural strength

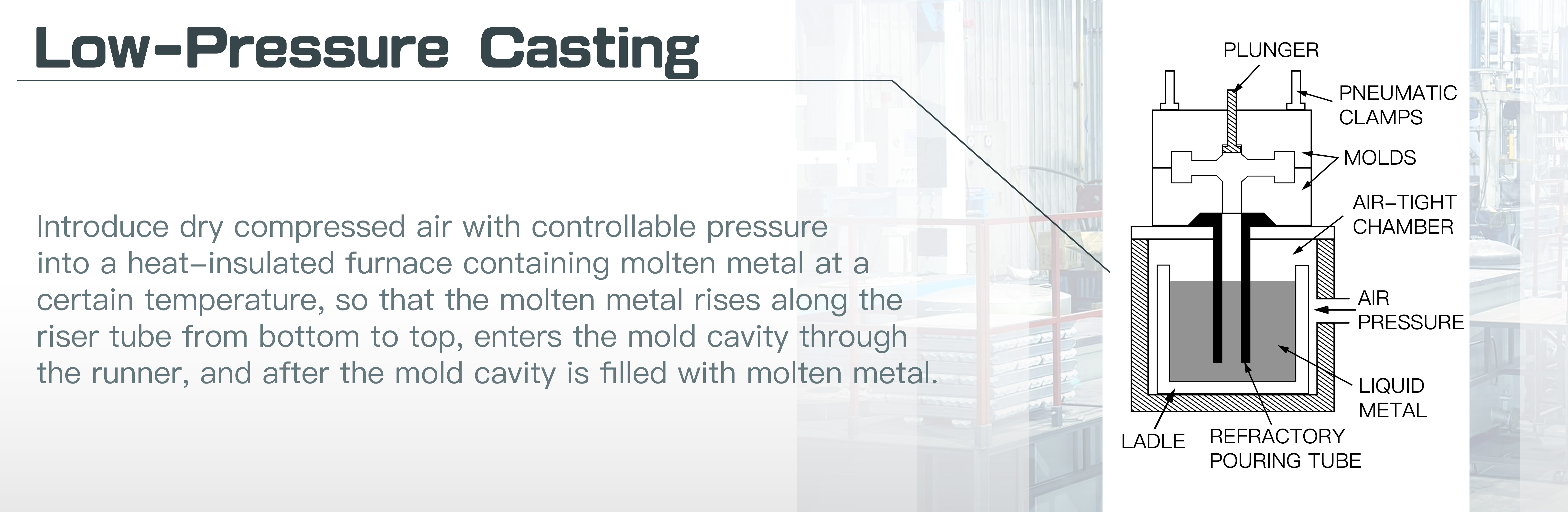

- The principle of low-pressure casting involves introducing pressure-controlled dry compressed air onto the surface of molten metal kept at a constant temperature in a holding furnace. This causes the molten metal to rise along a riser pipe from bottom to top, entering the mold cavity through a bypass. Once the molten metal fills the mold cavity, the air pressure is increased and maintained until the casting is completely solidified. The pressure is then released, allowing the unsolidified molten metal in the riser pipe and bypass to return to the holding furnace. This completes one casting process, and the desired casting is obtained after opening the mold.

Spec.

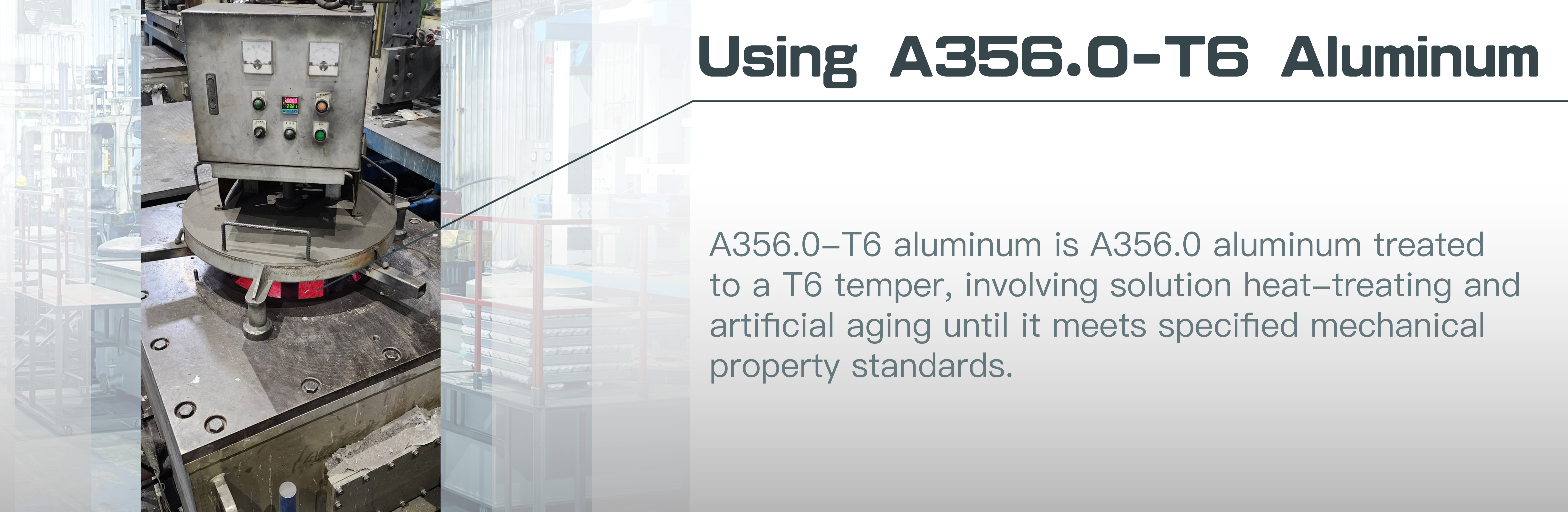

- Material: A356.0-T6

- Weight: 92.71 kgs

As a factory specializing in aluminum casting for arc extinction products, we take pride in our advanced low-pressure casting techniques. Our mobile side arc extinguishing barrel is specifically designed for the power distribution equipment industry, ensuring optimal performance and safety standards. We use aluminum for manufacturing, as it enables us to create lightweight finished products without compromising structural strength.

Our process begins with the principle of low-pressure casting, where pressure-controlled dry compressed air is introduced onto the surface of molten metal kept at a constant temperature in a holding furnace. This controlled introduction of air causes the molten metal to rise along a riser pipe from the bottom to the top, entering the mold cavity through a bypass. As the molten metal fills the mold cavity, the air pressure is increased and maintained until the casting is completely solidified. Subsequently, the pressure is released, allowing the unsolidified molten metal in the riser pipe and bypass to return to the holding furnace. This meticulous process ensures the creation of high-quality castings.

Our arc extinction products are made from A356.0-T6 aluminum alloy, known for its excellent mechanical properties and resistance to corrosion. A356.0-T6 aluminum is A356.0 aluminum in the T6 temper. To achieve this temper, the metal undergoes solution heat treatment and artificial aging until it meets the standard mechanical property requirements. After the heat treatment process, each product weighs approximately 92.71 kilograms, ensuring durability and longevity in demanding environments.

With our dedication to quality and innovation, we continue to push the boundaries of aluminum casting technology, providing our customers with reliable and high-performance arc extinction products for the power distribution equipment industry.

Our products in different indstries | Products and Services | |||||

FC/FCD casting | Alumimum alloy casting | Welding | Precision machining | Surface treatment | Assembling | |

Automobile Industry | ● | ● | ||||

Aeospace Industry | ● | |||||

Energy Equipment Industry | ● | ● | ● | ● | ● | ● |

Power Transmission Industry | ● | ● | ● | ● | ● | |

Machinery Equipment Industry | ● | ● | ● | ● | ● | ● |

Air Conditioning Equipment Industry | ● | ● | ● | ● | ● | |

Medical Equipment Industry | ● | ● | ||||

Electronics Components Industry | ● | ● | ● | ● | ● | |

Automation and Robotics Industry | ● | ● | ● | |||

Aluminum Casting Facility | ||||||

Brand | Type | Aquire Date | SN / Spec. | Process Capability | Appliance | Production Line Configuration |

Toyosaki | Resin Sand Recycling Equipment | 2010/10 | UDC-89PR | 5T/Hr | Furan Resin | Sand Mold Line - Molding |

Toyosaki | Resin Sand Mixing Equipment | 2010/10 | Customized | 10T/Hr | Furan Resin | Sand Mold Line - Molding |

Toyosaki | Resin Sand Mixing Equipment | 2010/10 | Customized | 3T/Hr | Furan Resin | Sand Mold Line - Molding |

Jnhaomai | Low Pressure Casting Equipment | 2011/03 | JZ455-500 | 500Kg | Aluminum | Sand Mold / Metal Mold Hybrid Line - Casting |

Jet-Shine | Low Pressure Casting Equipment | 2015/03 | JZ455-300 | 300Kg | Aluminum | Metal Mold Line - Casting |

Jet-Shine | Low Pressure Casting Equipment | 2017/8 | Customized | 300Kg | Aluminum | Metal Mold Line - Casting |

Jet-Shine | Low Pressure Casting Equipment | 2018/3 | Customized | 300Kg | Aluminum | Metal Mold Line - Casting |

Jet-Shine | Low Pressure Casting Equipment | 2022/12 | Customized | 700Kg | Aluminum | Sand Mold / Metal Mold Hybrid Line - Casting |

Jet-Shine | Low Pressure Casting Equipment | 2022/12 | Customized | 700Kg | Aluminum | Sand Mold / Metal Mold Hybrid Line - Casting |

Jnhaomai | Mobile Degassing Equipment | 2011/03 | Customized | ─ | Aluminum | Sand Mold Line - Smelting |

Kanghao | Hanging Degassing Equipment | 2017/05 | Customized | ─ | Aluminum | Metal Mold Line - Smelting |

HERSCHAL | Vacuum Hydrogen Meter | 2011/03 | GAS-TECHⅡ |

This is a notification message!

| ||