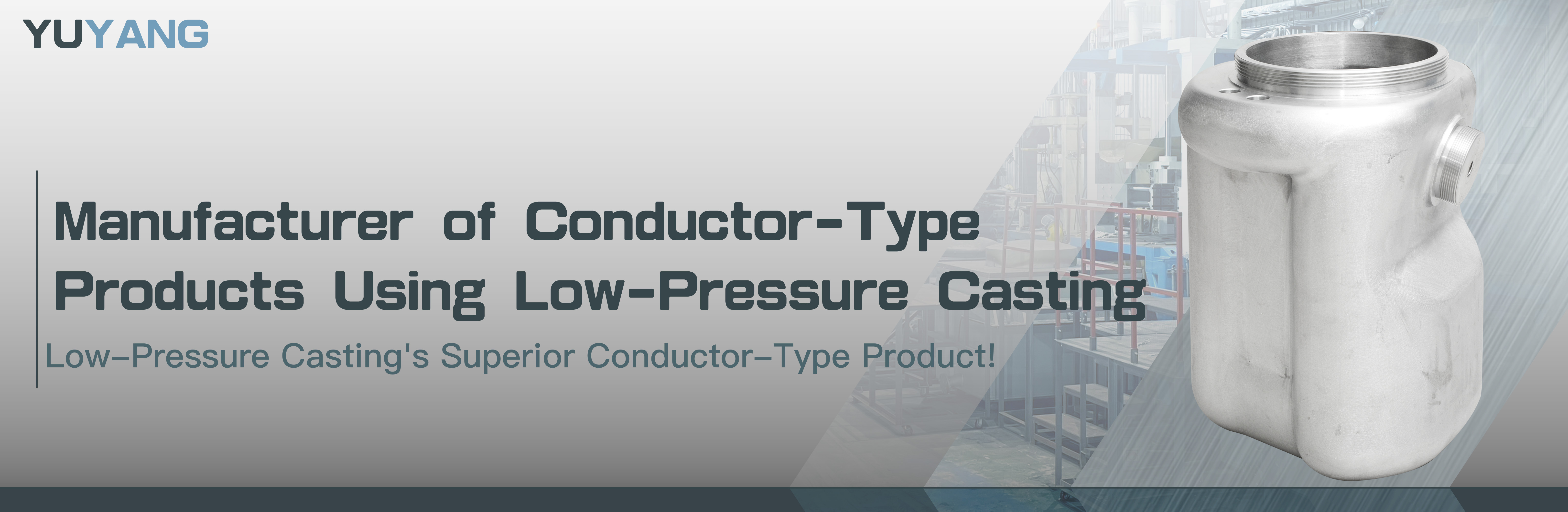

Manufacturer of Conductor-Type Products using Low-Pressure Casting

PID:

2733843

Model No:

0

Made in:

Taiwan

Quantity:

1000 Piece(s)Available

-

+

Payment:

Send Inquiry

Supplier Details

Yuyang Investment Co., Ltd.

Member Since

109

Address

4F., No. 308, Sec. 2, Zhongshan Rd., Bali Dist., New Taipei City

Contact Seller

View company information >

Key Features

As a prominent manufacturer of conductor-type products utilizing the low-pressure casting technique, we specialize in designing and manufacturing high-quality power transmission equipment. Our products are engineered for optimal performance, offering a perfect balance between lightweight construction and structural robustness. One of our key features is our use of aluminum in manufacturing. Aluminum is chosen for its exceptional properties, including its lightweight nature and impressive strength-to-weight ratio. This choice of material enables us to create products that are not only durable but also highly efficient in power transmission applications. Our commitment to quality extends to our manufacturing process, where each product undergoes rigorous testing to ensure it meets our stringent standards. Feel at liberty to get in touch with us.

Features

- Low-pressure casting

- Conductor type

- Power transmission equipment

- For the pursuit of lightweight finished products and structural strength, aluminum is selected for manufacturing

Spec.

- Material: A356.0-T6

- Weight: 11.5 kgs

As manufacturers of conductor-type products through low-pressure casting, our expertise lies in creating cutting-edge power transmission equipment that meets the stringent demands of modern industries. We specialize in crafting products that prioritize lightweight construction without compromising structural strength. To achieve this, we carefully select aluminum as our primary material due to its exceptional properties, which enable us to deliver finished products that excel in both performance and durability.

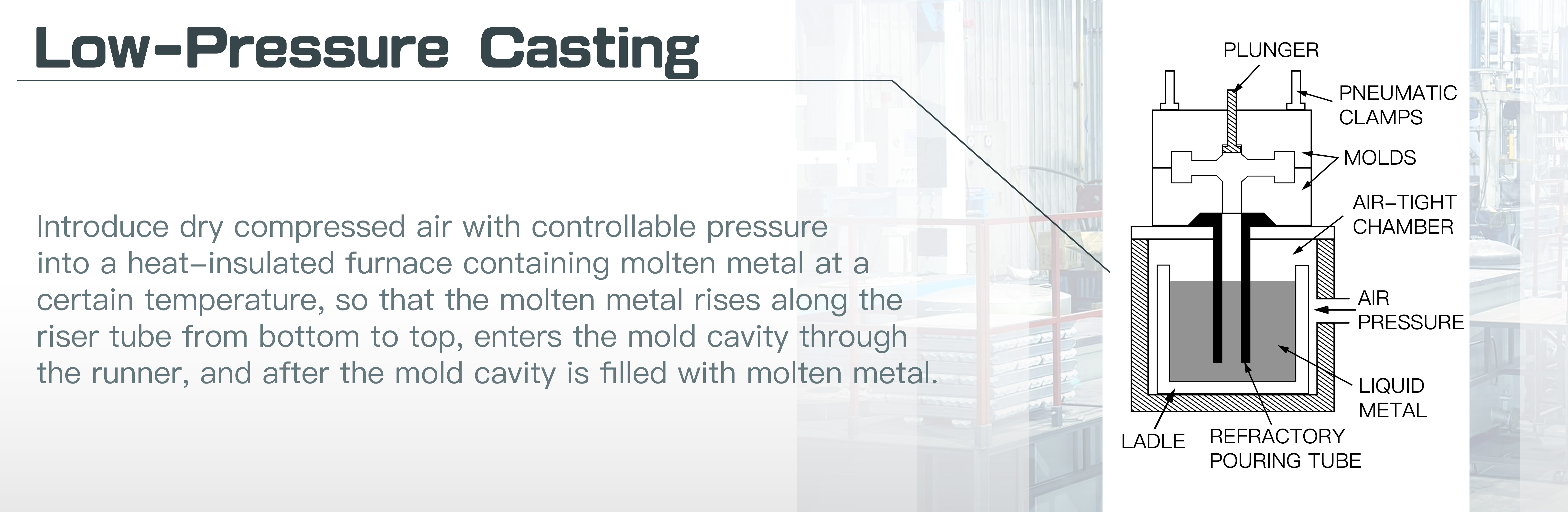

Our manufacturing process is centered around the principle of low-pressure casting, a method that ensures precise and consistent results. This process begins by introducing dry compressed air into a heat-insulated furnace containing molten metal at a specific temperature. As the air is introduced, the molten metal rises along a riser tube, entering the mold cavity through a runner. Once the mold cavity is filled, we increase the air pressure and maintain it on the liquid surface until the casting is completely solidified. Subsequently, the pressure is released, allowing any unsolidified molten metal in the riser tube and runner to fall back into the furnace. This meticulous process guarantees that each casting is completed with precision, resulting in the production of high-quality conductor-type products.

Our products are manufactured using A356.0-T6 aluminum, a specific grade selected for its excellent properties and suitability for our manufacturing processes. A356.0-T6 aluminum is A356.0 aluminum treated to a T6 temper, which involves solution heat-treating and artificial aging until it meets specified mechanical property standards. Each product weighs approximately 11.5 kilograms, providing an optimal balance of strength and weight for a wide range of applications in the power transmission industry.

At our state-of-the-art facility, we prioritize quality and precision in every step of our manufacturing process. From material selection to casting and finishing, we adhere to strict standards to ensure that our products meet the highest quality requirements. Our commitment to excellence has earned us a reputation for delivering conductor-type products that are reliable, durable, and tailored to meet the specific needs of our customers. Trust us to provide you with the highest quality power transmission equipment that is engineered to exceed your expectations.

The principle of low-pressure casting is to introduce dry compressed air with controllable pressure into a heat-insulated furnace containing molten metal at a certain temperature, so that the molten metal to rise along the riser tube from the bottom to the top, enter the mold cavity through the runner, and after the mold cavity is filled with molten metal, increase the air pressure is increased and maintain the gas pressure on the liquid surface until the casting is completely solidified, then release the pressure so that the un-solidified molten metal in the riser tube and runner falls back into the heat-insulated furnace. Thus, a casting process is completed, and the desired casting is obtained after the mold is opened.

| Our products in different indstries | Products and Services | |||||

| FC/FCD casting | Alumimum alloy casting | Welding | Precision machining | Surface treatment | Assembling | |

| Automobile Industry | ● | ● | ||||

| Aeospace Industry | ● | |||||

| Energy Equipment Industry | ● | ● | ● | ● | ● | ● |

| Power Transmission Industry | ● | ● | ● | ● | ● | |

| Machinery Equipment Industry | ● | ● | ● | ● | ● | ● |

| Air Conditioning Equipment Industry | ● | ● | ● | ● | ● | |

| Medical Equipment Industry | ● | ● | ||||

| Electronics Components Industry | ● | ● | ● | ● | ● | |

| Automation and Robotics Industry | ● | ● | ● | |||

Our products in different indstries | Products and Services | |||||

FC/FCD casting | Alumimum alloy casting | Welding | Precision machining | Surface treatment | Assembling | |

Automobile Industry | ● | ● | ||||

Aeospace Industry | ● | |||||

Energy Equipment Industry | ● | ● | ● | ● | ● | ● |

Power Transmission Industry | ● | ● | ● | ● | ● | |

Machinery Equipment Industry | ● | ● | ● | ● | ● | ● |

Air Conditioning Equipment Industry | ● | ● | ● | ● | ● | |

Medical Equipment Industry | ● | ● | ||||

Electronics Components Industry | ● | ● | ● | ● | ● | |

Automation and Robotics Industry | ● | ● | ● | |||

Aluminum Casting Facility | ||||||

Brand | Type | Aquire Date | SN / Spec. | Process Capability | Appliance | Production Line Configuration |

Toyosaki | Resin Sand Recycling Equipment | 2010/10 | UDC-89PR | 5T/Hr | Furan Resin | Sand Mold Line - Molding |

Toyosaki | Resin Sand Mixing Equipment | 2010/10 | Customized | 10T/Hr | Furan Resin | Sand Mold Line - Molding |

{

notification.classList.remove('show');

}, 3000);

}

function openFullscreen(image) {

const overlay = document.getElementById("fullscreen-overlay");

const fullscreenImage = document.getElementById("fullscreen-image");

fullscreenImage.src = image.src; // 将点击的图片源传递给全屏展示图片

overlay.style.display = "flex"; // 显示全屏容器

}

function closeFullscreen() {

const overlay = document.getElementById("fullscreen-overlay");

overlay.style.display = "none"; // 关闭全屏容器

}

document.addEventListener("DOMContentLoaded", function () {

// 打开弹窗函数

document.getElementById("send-inquiry").onclick = openPoterModal

document.getElementById("help-btn").onclick = openPoterModal

function openPoterModal() {

document.getElementById("poterOverlay").style.display = "block";

}

// 关闭弹窗函数

function closePoterModal() {

document.getElementById("poterOverlay").style.display = "none";

}

// 绑定关闭按钮点击事件

document.getElementById("poterCloseBtn").addEventListener("click", closePoterModal);

// 点击遮罩层外部区域关闭弹窗

document.getElementById("poterOverlay").addEventListener("click", function (e) {

if (e.target === this) {

closePoterModal();

}

});

let quantityInput = document.getElementById("quantity");

quantityInput.addEventListener("input", function () {

// 移除非数字字符

let newVal = this.value.replace(/[^0-9]/g, "");

this.value = newVal

$("#overlay-quantity").val(newVal)

});

let overlayQuantity = document.getElementById("overlay-quantity");

overlayQuantity.addEventListener("input", function () {

// 移除非数字字符

let newVal = this.value.replace(/[^0-9]/g, "");

this.value = newVal

$("#quantity").val(newVal)

});

$(".add-btn").click(function () {

let qty = parseInt($("#quantity").val())

console.log(qty);

if (qty) {

qty++

} else {

qty = 1

}

$("#quantity").val(qty)

$("#overlay-quantity").val(qty)

})

$(".subtract-btn").click(function () {

let qty = parseInt($("#quantity").val())

if (qty > 1) {

qty--

} else {

qty = 1

}

$("#quantity").val(qty)

$("#overlay-quantity").val(qty)

})

let productId = 2733843;

let supplierId = 1065947;

$(".form-submit").click(function () {

let params = {

productId: productId,

supplierId: supplierId,

est_amount: $("#est_amount").val(),

est_quantity: $("#quantity").val(),

email: $("#email").val(),

phone: $("#phone").val(),

message: $("#message").val(),

}

// 遍历 params 对象,检查是否有空值

for (let [key, value] of Object.entries(params)) {

if (!value) { // 检查是否为空或为0直接退出函数

return

}

}

$.ajax({

url: "/api/ProductReserve",

data: params,

method: "POST",

success: function (res) {

if (res.statusCode == 200) {

productId = null

supplierId = null

$("#est_amount").val("")

$("#quantity").val(1)

$("#overlay-quantity").val(1)

$("#email").val("")

$("#phone").val("")

$("#message").val("")

closePoterModal()

showNotification('Successfully');

} else {

alert(res.message)

}

}

})

})

})

| ||||||