As a supplier of grinding spindles known for excellent machining accuracy, we deliver products designed to meet your machining needs with precision and reliability.

Our spindles feature a built-in design that ensures seamless integration into your machining setup, enhancing overall efficiency and productivity.

One of the key features of our spindles is their lightweight design, which not only reduces the overall weight of your machining equipment but also contributes to smoother operation and reduced wear and tear.

Additionally, our spindles undergo a cryogenic treatment process, which results in minimal heat variation and exceptional machining accuracy, even during prolonged use. Feel free to contact us.

- Built-In Spindle

- Lightweight design.

- After the mandrel is cryogenically treated, the heat variable is small and the machining accuracy is excellent.

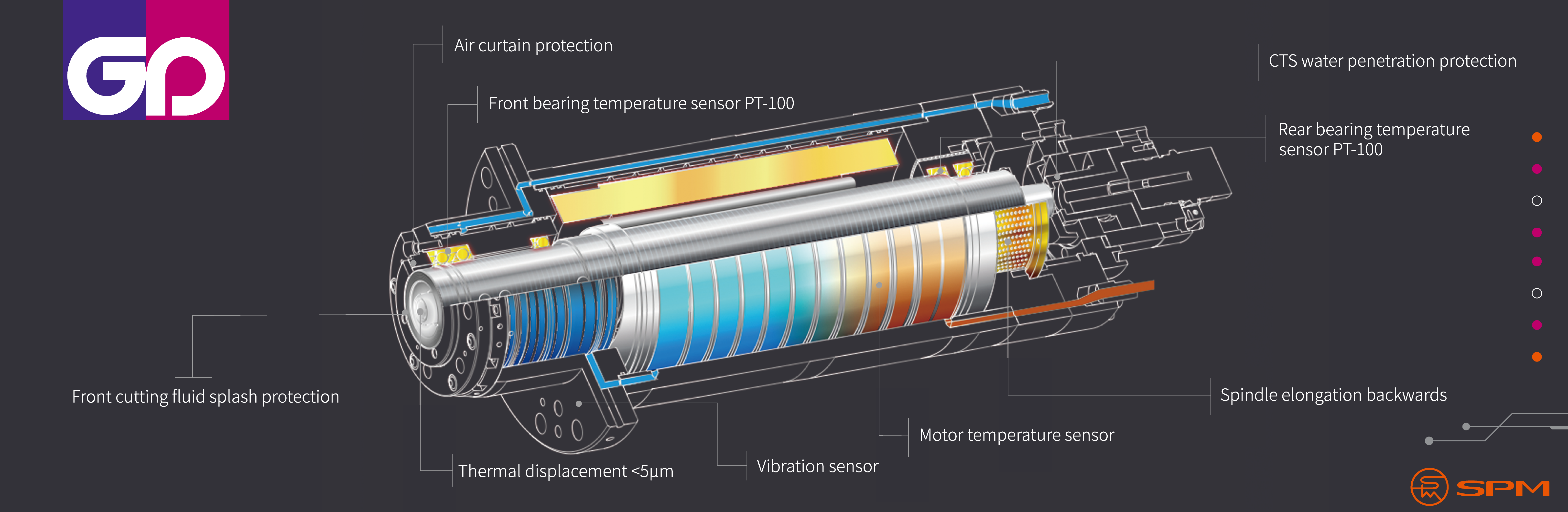

- The internal cooling system adopts spiral circulation to achieve high-efficiency operation.

- The spindle adopts ceramic ball bearings from Europe to achieve optimal power and excellent rigidity.

- With standard accessories bearing temperature sensor PT-100.

Service & Notes

- Warranty period is one year after sale.

- Complete after-sales service provided.

- Customizable specifications available.

Applications

- This milling spindle can be used in general and large or gantry milling machines.

- It can be used in machining applications such as large mechanical parts, wind power, and mold processing, etc.

Spec.

- Outer Diameter 230mm / S1: 26Kw / 124Nm / 8000rpm

- Motor Specification: ATE motor / Tool Type: HSK A100

- Spindle Dimension: 793mm

Product Description

As a supplier of grinding spindles with exceptional machining accuracy, our products are designed to meet the precise requirements of precision machining operations. Our spindles are designed with a focus on providing exceptional performance and reliability, making them well-suited for a wide variety of industrial applications.

One of the key features of our grinding spindles is their integrated design, which helps reduce weight and enhance overall stability during operation. This design also allows for easier integration into existing machining systems, making it an excellent choice for retrofitting or upgrading existing equipment.

Another standout feature of our spindles is the utilization of cryogenically treated mandrels. This treatment process minimizes heat variables, resulting in superior machining accuracy. The internal cooling system further enhances performance by ensuring efficient heat dissipation, enabling high-speed and high-precision operation.

Our spindles are also equipped with ceramic ball bearings sourced from Europe. These bearings provide optimal power transmission and excellent rigidity, ensuring stable and precise machining even under heavy loads. Additionally, our spindles come standard with a bearing temperature sensor (PT-100), enabling real-time monitoring to ensure safe and reliable operation.

In terms of specifications, our grinding spindles have an outer diameter of 230 mm and a power rating of 26 Kw, with a torque of 124 Nm, and a maximum speed of 8000 rpm. The motor is sourced from ATE motor in Germany, known for its quality and reliability. The spindle is designed to accommodate HSK A100 tooling, which is an industry standard, ensuring compatibility with a wide range of tooling options.

With a total spindle dimension of 793mm, our grinding spindles are suitable for a variety of machining applications, including grinding, milling, and drilling. Whether you're working with metals, plastics, or composites, our grinding spindles are the ideal choice for achieving precise and efficient machining results.