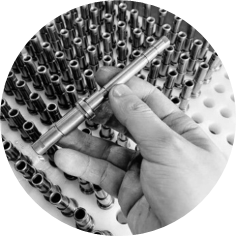

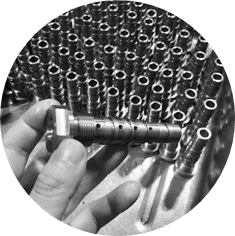

Professional CNC turning service, produce extremely intricate parts for your lathe. BUILD UP HARDWARE CO., LTD mainly engages in manufacturing and trading of all kinds of Custom CNC Machined Parts, such as Precision Aluminum Stainless Brass Parts, CNC Lathe Turning. We processing and manufacturing of all kinds of metal parts, such as screws, electrical, pneumatic tools, bicycles, clocks, instruments, medical equipment... and so on.

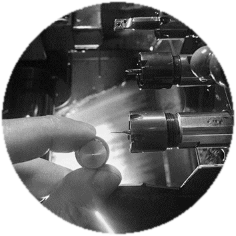

Sub Spindle & Back on CNC Lathe Machining

● Lathe Machining Diameter Size: 2mm ~ 36mm

● Machining Size: Within Ø 20mm x 400mm Length

● Machining Size: Ø 20mm ~ Ø 36mm x 120mm Length

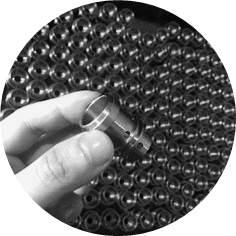

Custom CNC Machined Parts

CNC Lathe Machining Products | Specification |

| Material: Stainless steel 304 grade Size: Ø16.0*16.0mm Surface: Mill Finish Through the hole size: Ø0.4mm Depth: 2.0mm |

| Material: Stainless steel 630 grade Solution treatment solution zing Size: Ø17.15*55.6mm Turning and Milling

|

| Material: SCM440 Back inner diameter Ø3.95±0.05 round groove *2 sides |

| Material: SCM439 Blue cross steel Size: Ø16.4*31.4mm Lathe and milling at one-time forming

|

| Material: C1100 Copper

|

| Material: S45C medium carbon steel

|

| Material: SUS 304 stainless steel |

| Material: SCM440 Red Cross steel |

| Material: SUS440C Stainless steel |

| Material: SCM415 Green Cross steel Size: Ø29 *97.7mm Process: Internal and external teeth, Lateral foramen, Wrench groove Anterior Ø10 H7 |

| Material: SCM415 Green Cross steel Size: Ø29 *97.7mm Process: Internal and external teeth, Lateral foramen, Wrench groove Anterior Ø10 H7 |

| Material: 6061-T6 aluminum alloy Size: Ø31 *5mm Thickness: One side 1.2mm |

| Material: 6061-T6 Aluminum Alloy Size: Ø29mm*52mm Process: Single side 1mm thin shell Inner and Outer Teeth |

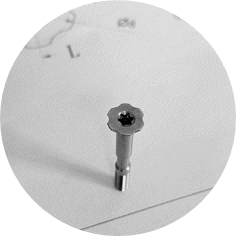

| Material: ASTM A681 A.K.A S7 Tool Steel Size: Ø13mm x 180mm Roundness: 0.01 mm

|

| Material: 6061-T6 Aluminum alloy Size: Ø28.4mm*15.8mm Process: Double face to angle guide |

| Material: SCM440 Red Cross steel Size: Ø24.1 *34mm Process: Inner hole tolerance 0.02 mm Heat treatment: Tempering to HRC 28° processing |

More Machining Parts video

Available Steel for Machinery

● Free Cutting Steels

● Bearing Steels

● Carbon Steels for Machine Structural use

● Manganese Steels for Machine Structural use

● Structural Steels with Specified Hardenability Bands

● Nickel Chromium Molybdenum Steels for Machine Structural use

● Chromium Molybdenum Steels for Machine Structural use

● Manganese Chromium Steels for Machine Structural use

● Nickel Chromium Steels for Machine Structural use

● Aluminum Chromium Molybdenum Steels for Machine Structural use

● Alloy Steel Bolting Materials High Temperature Service

● Alloy Steel Bars for Special Application Bolting Materials

● Carbon Tool Steels

● Alloy Tool Steels

● High Speed Tool Steels

● Spring Steels

Steel Data for Reference

| JIS | AISI/SAE | DIN | GB |

| SS400 | A36 | - | Q235 |

| (SS41) | |||

| S15C | SAE 1015 | CK15 | 15 |

| -1.1141 | |||

| S20C | SAE 1021 | CK20 | 20 |

| -1.0402 | |||

| S45C | SAE 1045 | CK45,C45 | 45 |

| -1.0503 | |||

| S50C | SAE 1050 | CK50 | 50 |

| -1.1213 | |||

| S55C | SAE 1055 | CK55 | 55 |

| -1.1203 | |||

| SCM415 | - | 15CrMo5 | 15CrMo |

| (SCM21) | -1.7262 | ||

| SCM420 | - | 25CrMo4 | 20CrMo |

|

Video

This is a notification message!

|