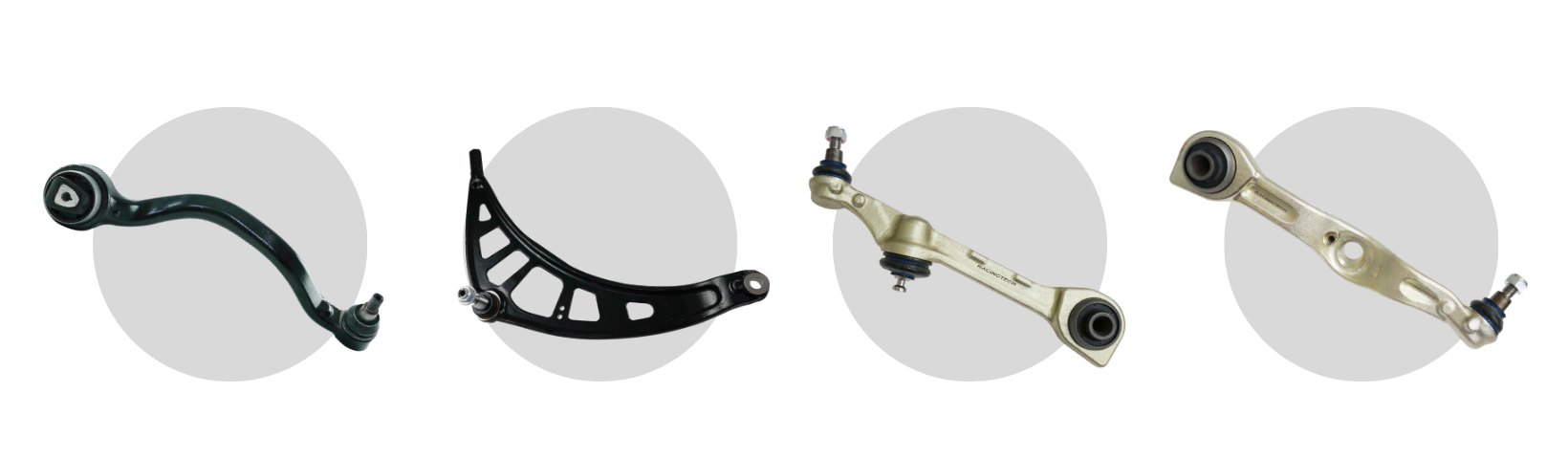

The Audi A4/A6 Car Suspension Control Arm is designed to move up and down with the spring when a car hits a bump or other road irregularity. It is a part of the suspension system that helps ensure your vehicle maintains full contact with the road at all times, providing you with the necessary control. If you're tempted, contact us right away to learn more!

The control arm allows you to steer a car while also guiding the wheels up and down with the road surface.Although it's simplistic in appearance, it has a vital role in a vehicle's overall stability and drivability.We provide products with safety and durability equivalent to any original equipment specification to fit a wide range of high-value international cars from Alfa Romeo to Volvo.

➤ Product Specification:

| OEM No. | 8E0 407 505B |

| RT No. | CA-AD0027 |

| Position | Front Upper LH |

| Built-in | A4 (8D2, B5) 1994 - 2001 A4 (8E2, B6) 2000 - 2004 A4 Avant (8D5, B5) 1994 - 2001 A4 Avant (8E5, B6) 2001 - 2004 A4 Convertible (8H7, B6, 8HE, B7) 2002 - 2009 A6 (4B2, C5) 1997 - 2005 A6 Avant (4B5, C5) 1997 - 2005 A8 (4D2, 4D8) 1994 - 2002 |

Customers can search for parts easily via our online catalogue.

RT keeps developing new items annually to meet customers' demands worldwide.

Material certificate and inspection report are essential documents we request for.

We're ISO9001 certified.

Check the quality of a commodity

Ensuring every item released under the Racing Tech

name is of stable quality by checking for alignment,

torque and vibration resistance, along with ensuring

the correct push-in and pullout characteristics on

relevant parts.

STEEL FORGING

● Use excellent carbon steel SAE1045 or alloy steel SAE4140 in production.

● Customization :

with heat treatment to ensure having good results in tensile and yield tests

DUCTILE IRON

● Use ductile iron which is good in strength and stiffness for production.

● We choose excellent automatic molding machine toensure stable speed when pouring material into the molds.Because it will lead

parts to unqualified stiffness if operators speed up or slow down the pouring speed.

ALUMINUM FORGING

● Insist using 6082 which according to genuine aluminum forging standard.

● Professio nal T6 heat treatment process to enhance stiffness and extend service life.

METAL PLATE

● Use the steel sheet particularly for automotive industry.

● With electroplating process to have excellent anti-corrosion.

● To control and offer a reliable quality parts to all our valuable customers,

We insist to implement tensile stiffness test and yield strength test.