Our thermoplastic rubber (TPR) compounds are formulated using Styrene-Butadiene-Styrene (SBS) or Styrene-Ethylene/Butylene-Styrene (SEBS) block copolymers. These materials possess many of the same properties as vulcanized rubbers but can be molded and extruded using conventional thermoplastic process equipment. Thermoplastic processing offers advantages over vulcanized, thermoset rubbers, which require a slower and costlier curing process. The majority of our TPR formulations are 100% recyclable and compliant with RoHS standards.

We play a crucial role in delivering top-quality TPR Thermoplastic Rubber to our clients. This thermoplastic rubber is processed in accordance with market quality standards and utilizing high-quality materials. Our expertise in providing this thermoplastic rubber to meet our customers' specific requirements makes us highly sought after. Additionally, we ensure timely delivery of this thermoplastic rubber at reasonable rates as promised to our customers. Our TPE offers the following benefits:

#The effective temperature range of mechanical properties can be as low as below -40°C and as high as above 135°C.

#Minimal permanent deformation under compression, short molding cycle, easy demolding, and high production

efficiency.

#Recyclable and can be reused, maintaining over 95% of its properties after being recycled 5 times, meeting

environmental requirements.

#Good resistance to aging, ozone, and weather conditions.

#Excellent wear resistance and tear resistance, with high tensile strength, flexural strength, and elongation at break.

#Good low-temperature resistance, oil resistance, and resistance to oxidation, UV, and aging.

#Compatible with PC and PC/ABS for two-color combinations.

#Finished products have a pleasant tactile sensation, non-slip properties, excellent flexibility when bent, and sweat

resistance.

# Available in natural and black colors.

#We are also capable of producing nano-sized nano silver antibacterial thermoplastic elastomer (TPE) masterbatch that meets the approval of the Industrial Technology Research Institute.

Applications:

Electronic equipment Screw-on feet made of TPR are highly effective in preventing slippage. Similar to TPE, TPR exhibits excellent vibration-damping properties, making it an ideal material for feet. Its ability to damp vibrations also makes it a commonly used material for workers' gloves. |  |

Sheet metal fabrication Blanking plugs serve as effective protection against sharp edges and are perfect for closing panel cavities. Also known as hole plugs, they safeguard against dust and moisture during the cleaning and manufacturing process. |  |

Cabinets ITPR wheels are the ideal castors for heavy-duty applications such as cabinets, trolleys, waste equipment, and workstations. These wheels offer excellent shock absorption and protect floors with their quiet rolling operation. Additionally, they are resistant to cleaning chemicals, ensuring durability in demanding environments. |  |

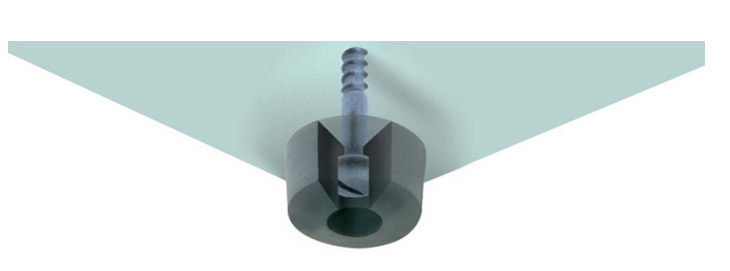

Manufacturing TPR side pull plugs are utilized to safeguard threaded or plain components from contamination and damage during transportation, with automotive parts being a prime example. These plugs are designed with a side pull tab for easy and swift removal. Their tapered design enables them to fit various inner diameters while providing resistance to chemicals and contaminants. They are especially suitable for applications in hard-to-reach positions. |  |