Production Features:

➲ Graphene Surface:Graphene heatsink demonstrated outstanding cooling performance which was superior to copper or aluminum heatsink with the same dimension and same power input. With unparalleled thermal conductivity of 5300W/m·K, graphene outperforms other heat conductors, such as pure copper at 386.4W/m·K and aluminum at 237.2W/m·K. By leveraging temperature monitoring software to compare the heat levels pre and post installation, you will discover that graphene-coated heat sinks exhibit superior efficiency compared to their counterparts.

➲ Extended Lifespan: By reducing the risk of overheating, our graphene-coated heatsinks not only protect your components but also significantly extend their lifespan. This added longevity translates into cost savings, making our product an investment that pays off in the long run.

➲ Ultra-Thin Design: The utilization of ultra-thin graphene aluminum foil heatsink labels successfully mitigates all assembly-related mechanical issues. Further, these heatsinks are compatible with the in-built heatsinks of an M.2 slot on a motherboard, promising dual-cooling functionality and assuring unwavering, top-tier performance.

With our exceptional graphene-coated heatsinks, we're committed to offering superior cooling solutions that boost your device's performance and reliability. Choose us for quality, efficiency, and peace of mind.

Production Specification:

1. Size: 24x70x4Hmm

2. Heatsink Material: Aluminum

3. Surface Treatment: Graphene Coated

4. Pad: Thermal pad (K=3.8)

5. Decoration: Add logo is available

6. MOQ: Small quantity is acceptable (Least 200 Pcs)

Other Type Graphene Coated Heat Sinks :

| |

| SS-M20020-AGP00T |

| SS-M20050-AGP00T |

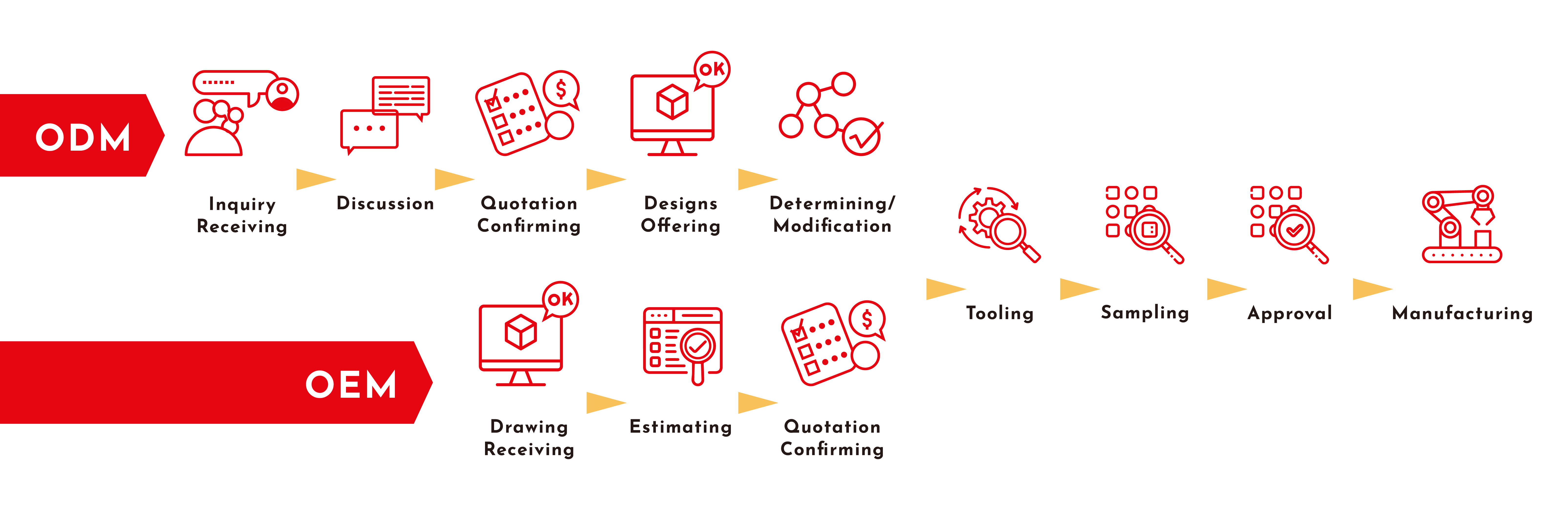

Heatsink ODM & OEM Service:

➲ Custom Design: We offer a comprehensive design service for heatsinks, tailored to meet your unique needs and specifications. Our team of expert engineers is proficient in devising effective, efficient, and innovative cooling solutions, making sure your product performs optimally.

➲ Material Selection: Based on your product requirements and intended applications, we provide guidance on the most suitable heatsink materials, including the revolutionary graphene, to ensure optimal thermal conductivity and long-lasting durability.

➲ Prototype Development: We take care of all stages of prototyping, from the initial concept design to the production of a physical prototype. This allows you to evaluate the design and performance before proceeding with full-scale production.

➲ Mass Production: After design approval and successful prototyping, we manage the mass production of your heatsinks, maintaining high standards of quality control to ensure each unit meets the set specifications.

➲ Packaging & Delivery: We offer customizable packaging solutions and ensure reliable delivery of your orders, regardless of the size or destination, to make sure your products reach you or your customers safely and on time.

With our Heatsink ODM & OEM services, you can rest assured that you're receiving a comprehensive, turnkey solution that covers everything from design to delivery. We strive to provide you with the highest quality heatsinks, made to enhance the performance and reliability of your devices.

SIN FAY OEM/ODM Advantages:

We provide high-quality stainless brackets for machine assembly production, and solutions are based on your needs, not only professional stamping technology, surface, and plating. In terms of quality control, we can meet strict tolerance requirements and reduce defective parts. Welcome to your inquiry!

➲ We provide solutions for different industries.

➲ Applications: Comprehensive range of materials can be used.

➲ Customizable: Metal stamping tags and bracelets can be customized with a variety of shapes, sizes, and colors.

About Sin Fay:

Established in 1969, Sinfay was originally located in Sanchuang, Taiwan, and started a stamping business with watch chains and shaves. In 1977 started to export business. In 1985, Sinfay relocated to Taoyuan to better meet the demand for increasing production.

Specializing in various stamping parts and persisting top-quality products, we have specially designed and produced all dies and molds used in the course of production.

The dies and parts we produce include:

➲ Regular stamping dies/parts

➲ Progressive dies/parts

➲ Extraction and expansion dies/parts

➲ We strive to meet clients’ demands in any way possible. Our products include but are not limited to copper, aluminum, tin, stainless steel, Mylar and etc.

➲ We can provide a variety of materials as clients requested.

To better meet the demand of the ever-changing market, our company never ceased improving and innovating; currently, we have extended the product line to communication and optoelectronic parts.

We value existing and prospective clients with the same respect and offer them the same courtesy. We strive to help our clients enhance the competitiveness of their products and result in win-win outcomes with top-quality products, the shortest delivery date, and the most competitive price.