R-Series Cone Crusher

R-Series Cone Crusher designed by FONG CHUAN R&D team, has a hydraulic adjusting system for cooling, which enables to adjust the setting of the crushing cavity by the Programmable Logic Controller without the need for manual means of turning it out. The control signals of the PLC identify the status of the machine and guarantee a stable and safe production. Hydraulic adjustment system allows for easy and higher efficient liner replacement.

- Product Design

R-Series Cone Crusher equipped with reliable hydraulic tramp release allows the clearing and the blocking materials of the crusher cavity to be processed without loosening spring bolts or disruption of production.

Also, the oscillating shafts made of Ni-Cr-Mo steel ensure an outstanding strength and stability, and the high manganese steel made crushing plates facilitate better quality of crushing. The premium mantle and concave simplify the process of turning the bowl for liner change.

- Manufacture

Based on years of experience in manufacturing crushing equipment, R-Series Cone Crusher manufactured by our company has a high crushing capacity and efficiency. The easy-to-operate unique chamber design improves reduction ratio, productivity for coarse and fine crushing application.

- Benefits

- Excellent productivity with low energy consumption.

- Fine-quality product with low reworking rate (i.e. less over size product).

- Extensive application.

- Low cost for maintenance.

- Easy to operate, no staff is needed to be charged with the supervisory duty.

- Turnkey Plant

The cone crusher is now widely used in areas like secondary and tertiary crushing of hard rock and gravel aggregate, crushing work for resource recycling treatment, incinerator residue segregation, solid waste processing, smelting by-product isolation and sorting of building materials for remanufacturing purpose.

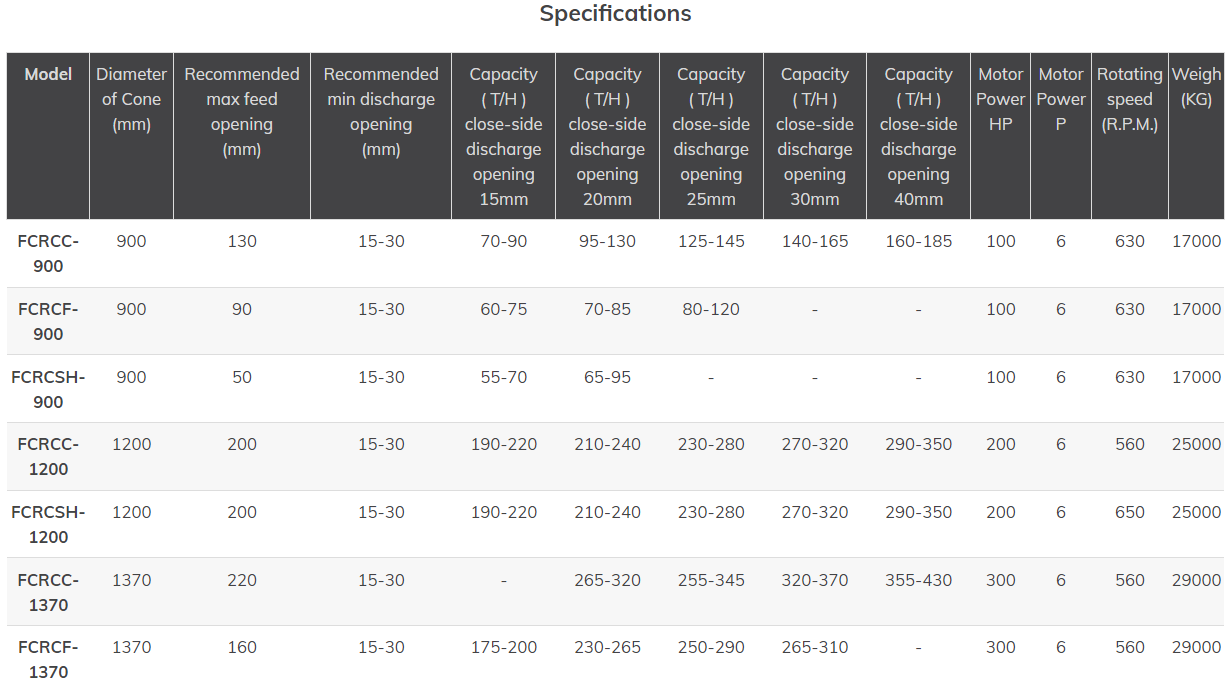

Note : Technical data may change due the technical progress. Specifications and dimensions are subject to modification without notice.