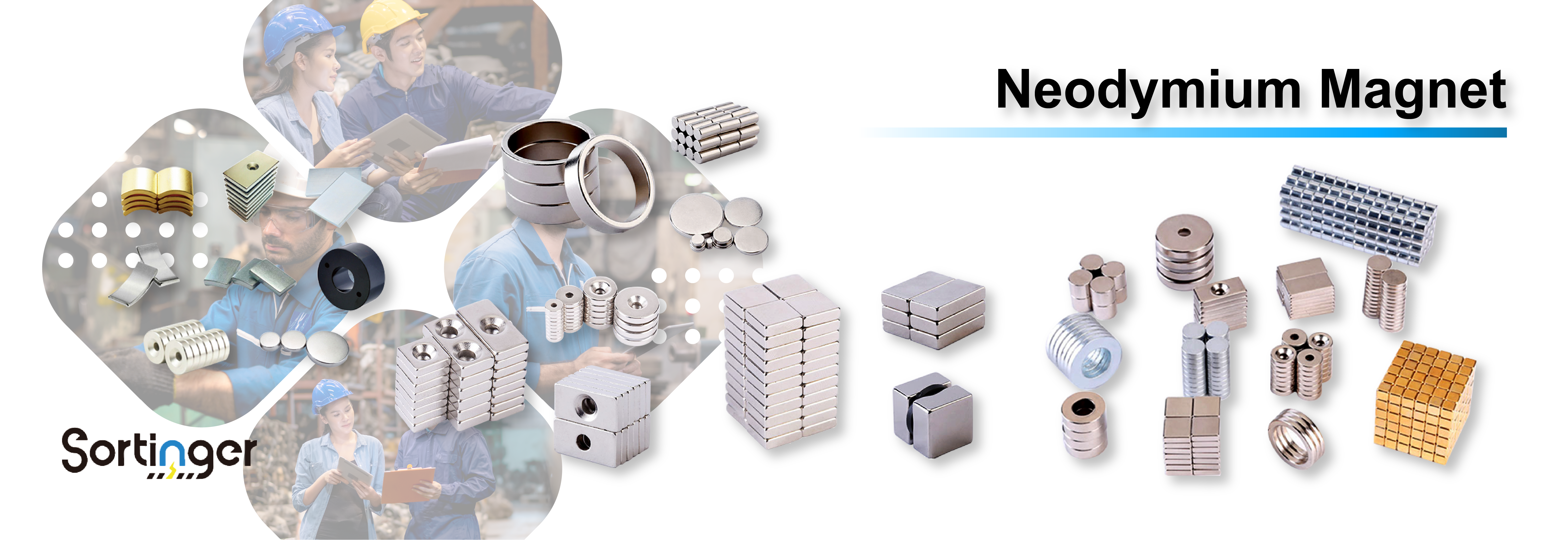

Strong Neodymium Magnet

Neodymium magnets (also known as “NdFeB”, “Neo” or “NIB” magnets), are strong permanent magnets made from an alloy of neodymium, iron & boron. Part of the Rare-Earth magnet family, they have the highest magnetic properties of all permanent magnets. Due to their high magnetic strength and relatively low-cost, they are the preferred choice for many consumer, commercial, industrial and technical applications.

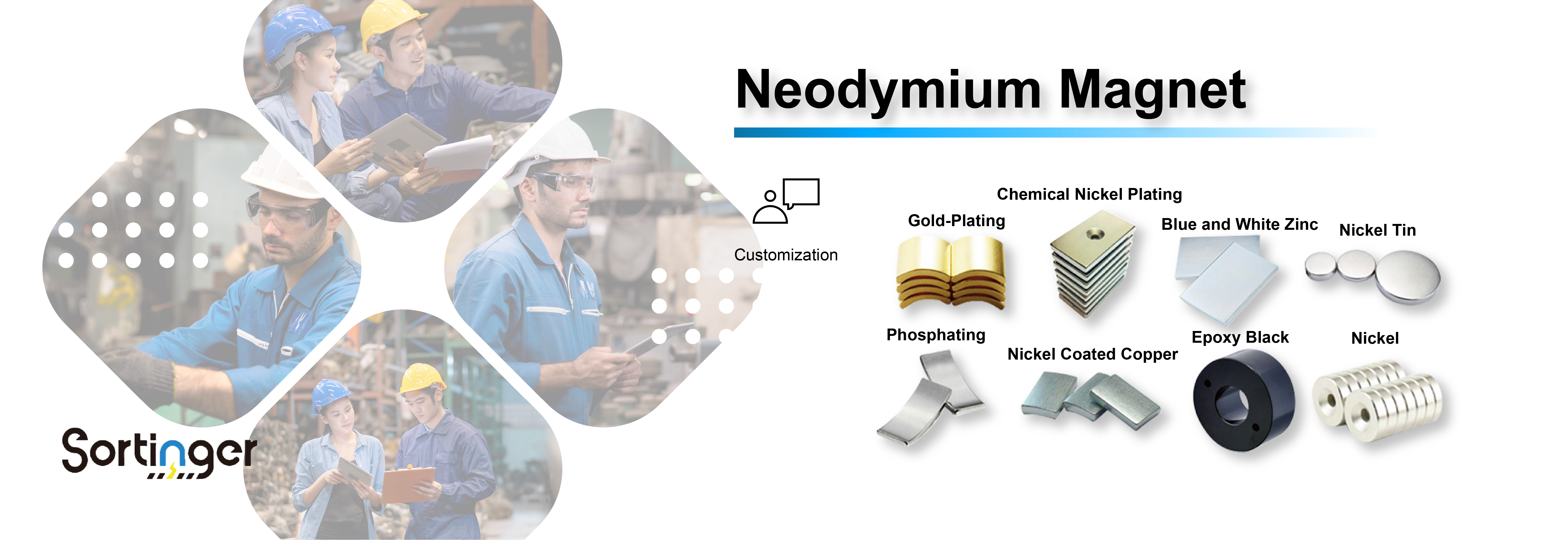

Product Specifications:

- Shape, size, magnetic strength and alignment, a plating method, and other parameters can be customized.

Product Features:

- Strong magnetic force

- High corrosion resistance after electroplating

- Not easy to demagnetize

- Value for money

- hard texture

Sintered Ferrite Magnet

- Produce by powder metallurgical method

- Chemical composition of Ba/Sr 0.6 Fe2O3

- Relatively brittle & hard

- Good resistance to demagnetization

- Excellent corrosion resistance

- Raw material is readily available & low in cost

- Good temperature stability

- Most widely used permanent magnets

Neodymium-Rare Earth Magnet, Sintered

- Produce by powder metallurgical melthod with chemical compostition of Nd2Fe14B

- Very brittle & hard

- Poorest corrosion resistance of all commercial MAGNET material

- High resistance to demangnetization

- Excellent cost to performance ratio

- Reasonable temperture stability

- Not suitable for application which exposed in high temperture conditions

Injection Bonded Magnet

- Composition of hard ferrite or rare earth magnet powders are embedded in thermoplastic and formed on injecton moulding machine.

- It is possible to incorporate shafts or other insert to

- the magnet during manufacturing process

- Vareties of shapes can be manufactured.Such as gears, thin ring and many other complicated forms

- Good resistance to corrosion and chips

- All or only part of the magnet can be magnetized

Samarium-Rare Earth Magnet, Sintered

- An alloy compose of SmCo5/Sm2Co17 Produce by powder metallurgical method

- Extremely hard & brittle

- High demagnetization resistance

- Limited raw material supply resuit high in cost

- Outstanding thermal stability

- Excellent anti-corrosion properties

Alnico Magnets

- Produce by casting or powder metallurgical techniques

- An alloy composed of matrix of AI-Ni-Fe-Co

- Very hard & brittle

- Poor resistance to demagnetization

- Produce good flux density at an reasonable cost

- Excellent stability over a wide temperature range

Magnetic Pothook

- Anisotropic Ferrite or NdFeB magnet set in mild steel housing, available in mary different form and shape. Adhesive force can be reached 32Kgs.

- MAGNET Systems for Consumer Application:MAGNET name badges/MAGNET clothing button

- Superficial treatment: Roast various paint,e.g.

- electrogalvanizing or nickel

Established in 1986, Nian Hung began with the design and manufacture of powerful magnets (e.g., Neodymium, Ferrite, Samarium Cobalt, Aluminum Nickel Cobalt, Rubber, etc.) and later expanded their product range by delving into the research and development of various types of magnetic sorting/separation equipment applicable to different industries such as waste recycling, metal recycling, rubber & plastic recycling, incineration slag & ashes, food processing, mineral processing, aggregate, textile, petrochemicals, pharmaceuticals, etc.

Nian Hung continues to focus on the innovation of magnetic sortation/separation technology while striving to transform how we obtain, use, and reuse the planet's resources to enable a world without waste. With almost four decades of experience, Nian Hung can put forward custom, integrated solutions to meet customers’ requirements promptly.

-480x480.png)

-480x480.png)

-480x480.png)

-480x480.png)

-480x480.png)