Service:

1 year Quality guarantee

Material supply solution

Online after sales service

Introduction:

100% design and made in Taiwan.

The automatic paper burger box thermoforming machine is a fully automatic paper forming machine with the advantages of high speed and convenient operation.

This model uses a self-contained hot air generator for single PE coated paper. It is used to produce single-color disposable paper lunch boxes through automatic feeding, heating (with hot air generating device), hot press forming (four corners of bonded lunch boxes), automatic point collection, and microcomputer control. Paper lunch boxes, cake tray, food packaging boxes, etc.

Mechanical transmission, speed, energy saving, stability, and easy operation.

Detail:

· Available material:

Single-sided PE food cardboard

Double-sided PE food cardboard

Recycling environmentally friendly PE coated paper

200-400gsm PE craft paper

PE cardboard paper (No plasticizer/food-grade wrapping paper/qualified for FDA inspection)

PP coated paper

Isla Duo paper board

Plastic free paper material

Environmentally friendly food grade cardboard that can be naturally degraded without plastic components

The minimum plastic content can be less than 5%

· Output (/Mold) :

Disposable Paper lunch box

Disposable takeout wrapping paper lunch box

Burger Box

American Hot Dog Box

Chinese food paper lunch box

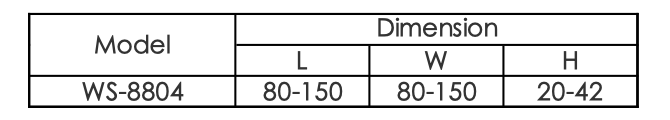

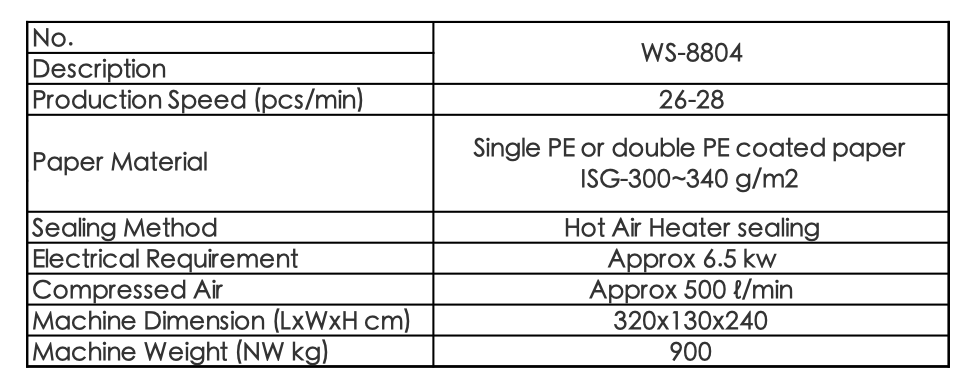

Specifications:

Advantage:

Multi-purpose equipment, simple mold change design:

It can make products of different sizes; the mold change time is less than 30 minutes; the adjustment paper only needs less than 5 sheets.

Receiving box/packing method:

Collect and stack together, and automatically count, saving operators, one person can operate 3~5 units.

Two production lines:

Different molds can be installed at the same time to produce different products

Temperature control system:

Can be adjusted according to different paper quality - circuit protection design.

Plan an automatic packaging production line, and make an automatic production line for large-scale production.

Save on paper costs.

24 hr producing available , lowest producing reject ratio.

The equipment can be customized for oven heating and microwave heating for food paper containers.