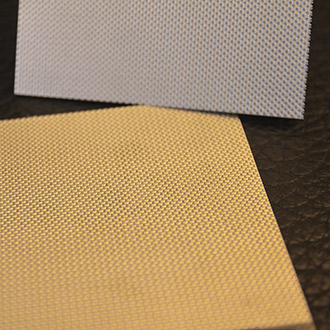

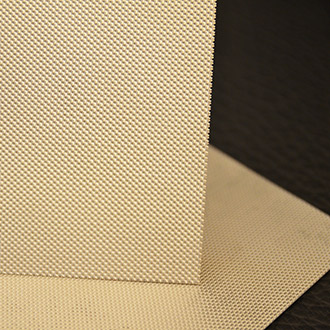

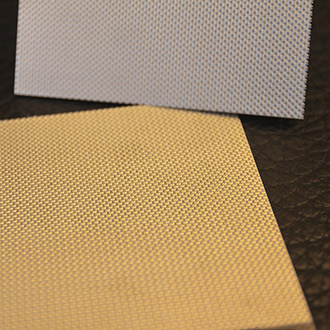

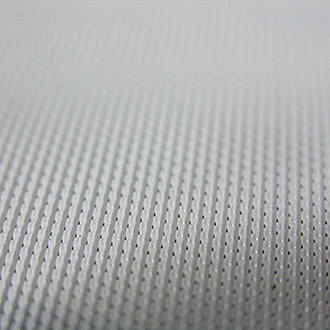

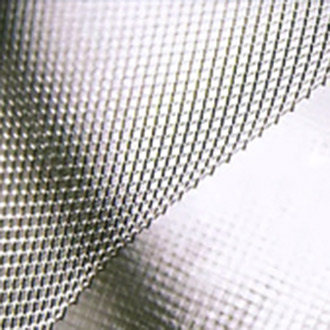

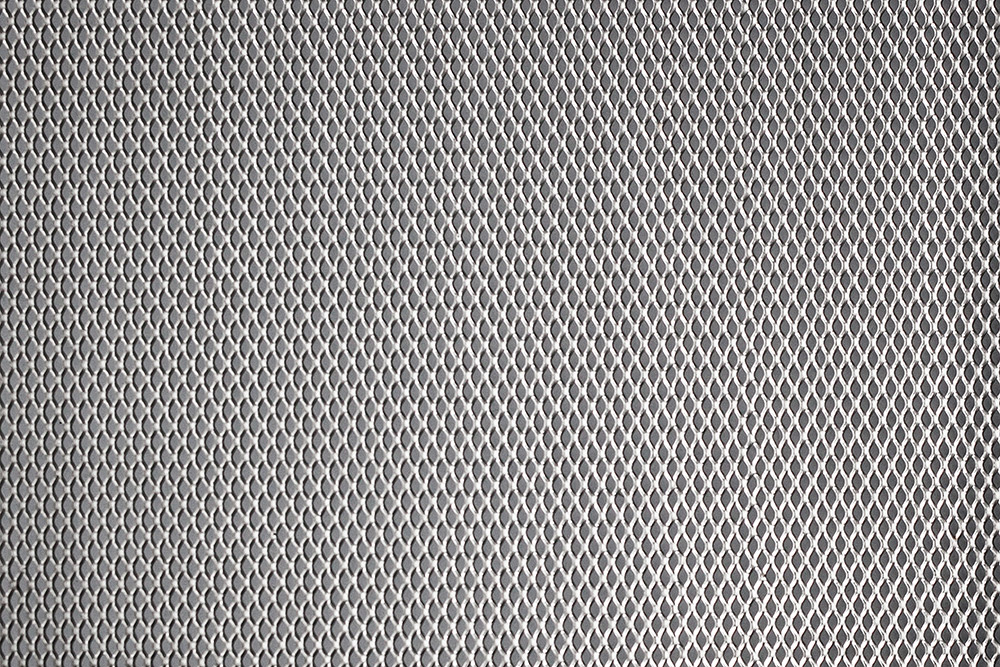

Micro expanded metal mesh is special expanded metal with very small openings. The characteristics of micro mesh such as high conductivity, sound absorption and ability of refraction have expanded the aspects of its utilizations. The key factor of micro mesh expanded metal application is material. The most common materials of micro mesh are mild steel, aluminum, stainless steel, copper, nickel, titanium and other alloys.

| Name | Strand Size (MM) | Mesh Size (MM) | Open Area | ||

|---|---|---|---|---|---|

| ID No. | T | W | SW | LW | % |

| JM-01-06 | 1.0 | 1.0 | 0.06 | 2 | |

| JM-01-05 | 0.1 | 0.1 | 0.5 | 1 | |

| JM-01-01 | 0.1 | 0.1 | 1 | 2 | |

| JM-03-02 | 0.3 | 0.3 | 2 | 4 | |

| JM-15-16 | 0.15 | 1.9 | 1.6 | 2.4 | |

Applications:

- Current-collecting expanded metal grids

- Heat Transfer/Cooling system: e.g. Heat Sinks

- Aero Devices: e.g. Lightning Strike Protection

- Electronic shielding: e.g. EMI/RFI Shielding

- Sound Insulation: e.g. Acoustic Ceilings

- Medical, Automotive, Chemical, Mining, Filtration, Segregation and Petroleum industry

Material: steel, mild steel, aluminum, galvanized, copper, nickel, chromium, titanium and other different materials

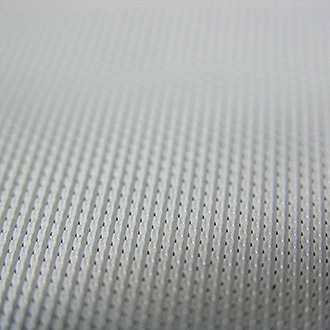

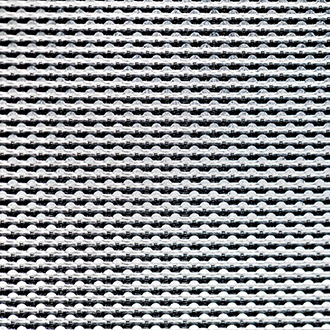

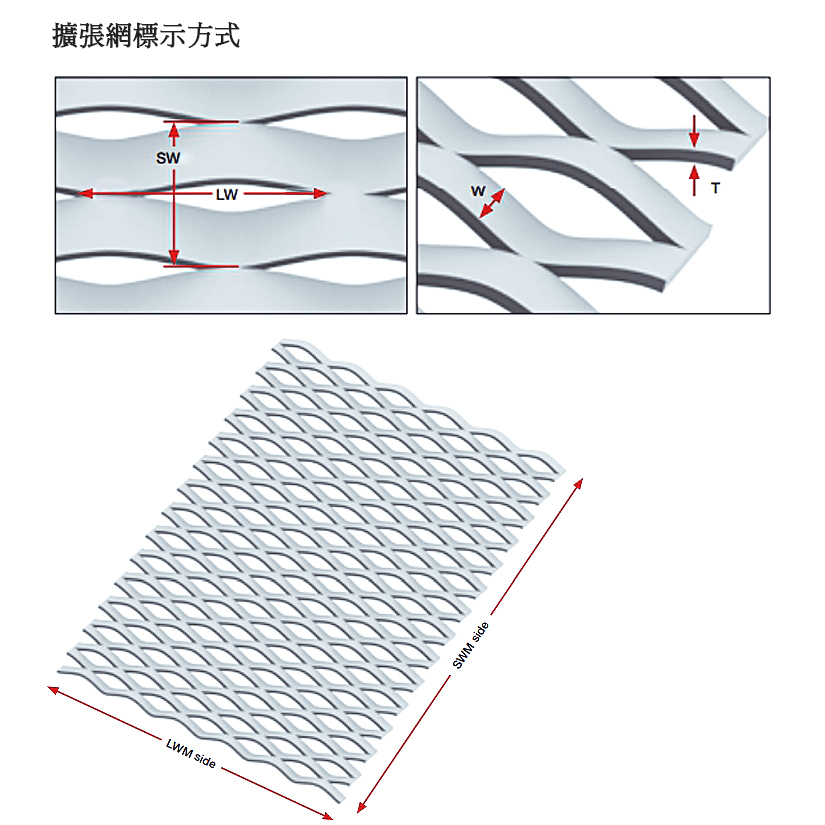

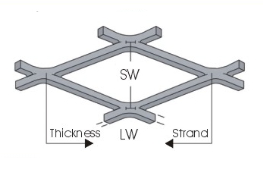

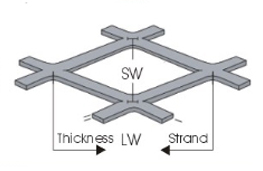

T (Thickness): Plate Thickness

W (Width): Strand width

SW: Short way dimension of mesh

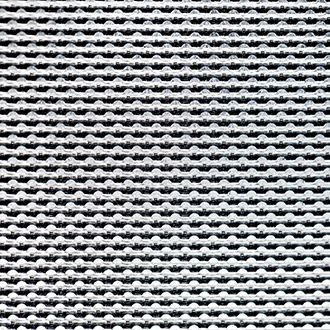

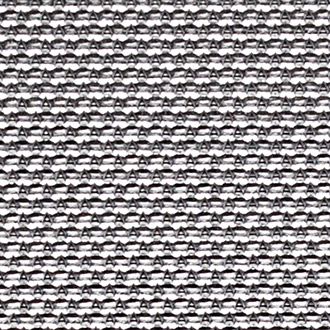

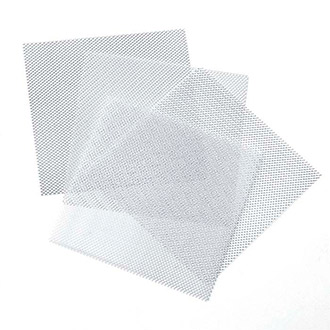

LW: Long way dimension of mesh The illustrations show the correct way to designate SW and LW dimensions in relation to the length or width.

The illustrations show the correct way to designate SW and LW dimensions in relation to the length or width.

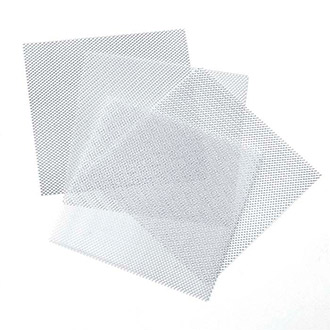

| 【Standard】 | 【Flatten】 |

|  |