We are able to machine these earphone metal housing parts with CNC turning technique, automatic lathes and many other CNC equipment which allow us to produce custom metal material brass/steel/aluminum/stainless steel of CNC earphone housing, meeting the exact specifications required.

The surface treatment of metal earphone shell CNC turning service can be treated in many ways, mainly includes anodized, electroplating, spraying, laser engraving and so on.

Our turned and milled parts meet the highest requirements regarding accuracy, stability and surface finish quality.

On request we are happy to organize further process steps such as anodizing, laser marking and cleanroom services for our customers.

CNC earphones metal housing are widely used in computer communications, office equipment, electronic appliances, automotive manufacturing, mechanical equipment, instrumentation, sports equipment, decoration engineering and other industries.

Production Facility

∞ CNC turning and milling lathe is equipped with automatic bar feeder which incomes the outside diameter from 1mm~50mm.

∞ Good at small hole diameter processing. The actual processing hole diameter is 0.65mm.

∞ Our in-house secondary facilities increase the value of product by all-in-one step.

∞ Exact production control from material incoming to warehouse management

Material

| Material | No. |

| Titanium | CP1~CP4、 Ti-6AL-4V |

| Magnesium | Magnesium alloy |

| Stainless Steel | SUS303、 SUS304、 SUS316、 SUS420、 SUS440C |

| Carbon Steel | S15C~S45C |

| Aluminum | AL2011、 AL6061、 AL7075、 AL5056 |

| Brass/Copper | C3602、C3604 、C6802、C17700、C2600 |

| Plastic | POM、TEFLON |

| Free Cutting Steel | 12L14、12L15 |

| Steel for Specific Purpose | SUJ2 |

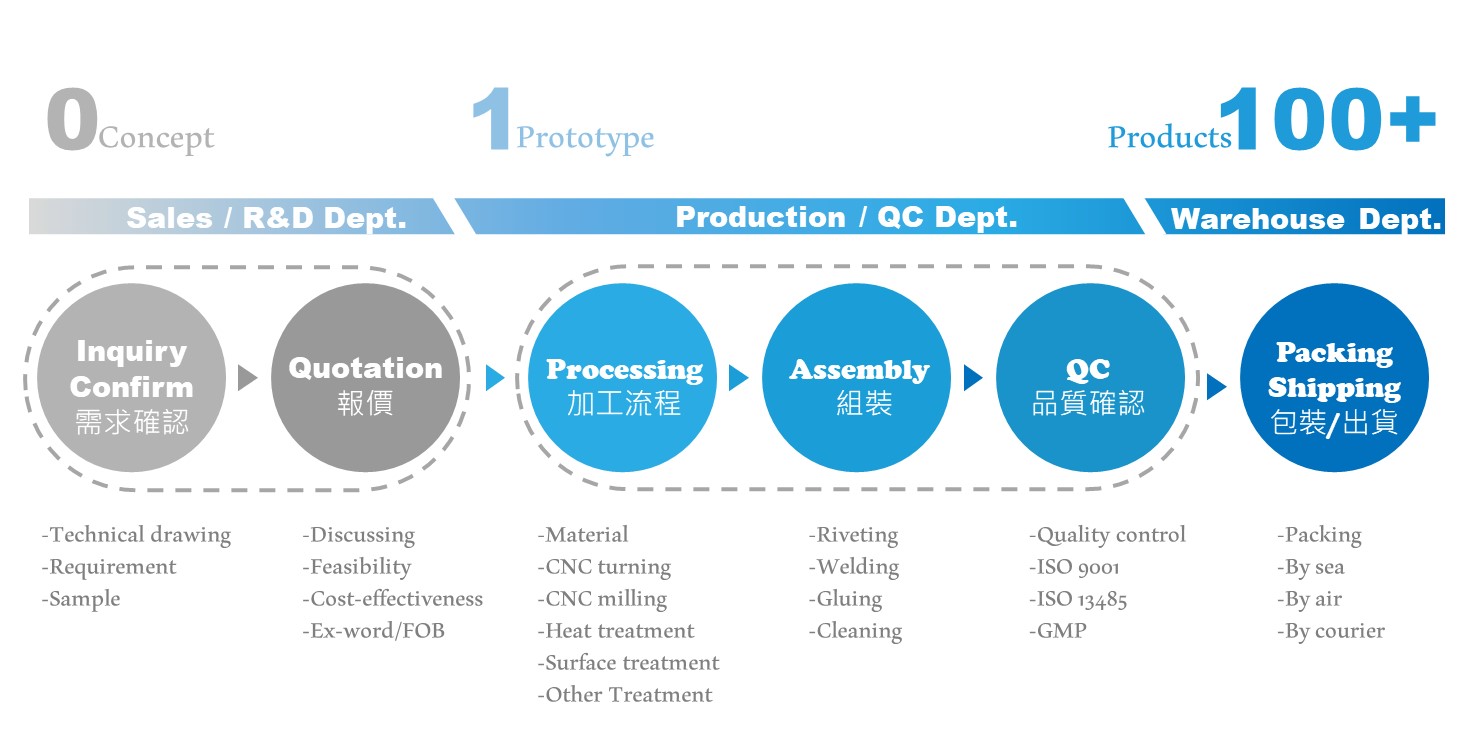

Service Flow

Welcome to send us the drawing, samples, your ideas to us for further cooperation.

Other Process

| Heat Treatment | Surface Treatment | Others Process | |||||

| QPQ | Normalizing | Gold plating | Anodizing | Grinding | Laser carving | ||

| LCN | Thermal refining | Nickel plating | Passivate | Polishing | Sand blasting | ||

| GSN | Carburizing | Zinc plating | Blackening | Tumbling | NYLOK | ||

| Vacuum | High frequency | Chrome plating | Teflon treatment | MIM | Geomet | ||

| Nitriding | Annealing | Phosphating | DLC | Ultrasonic cleaning | Powder Metallurgy | ||

Packing

Paper roll, PP Bag, Blister box, Carton, Crated Box, Tray and so on, ODM packing is acceptable.

Delivery

By sea, by air, by courier, by express.

Contact US