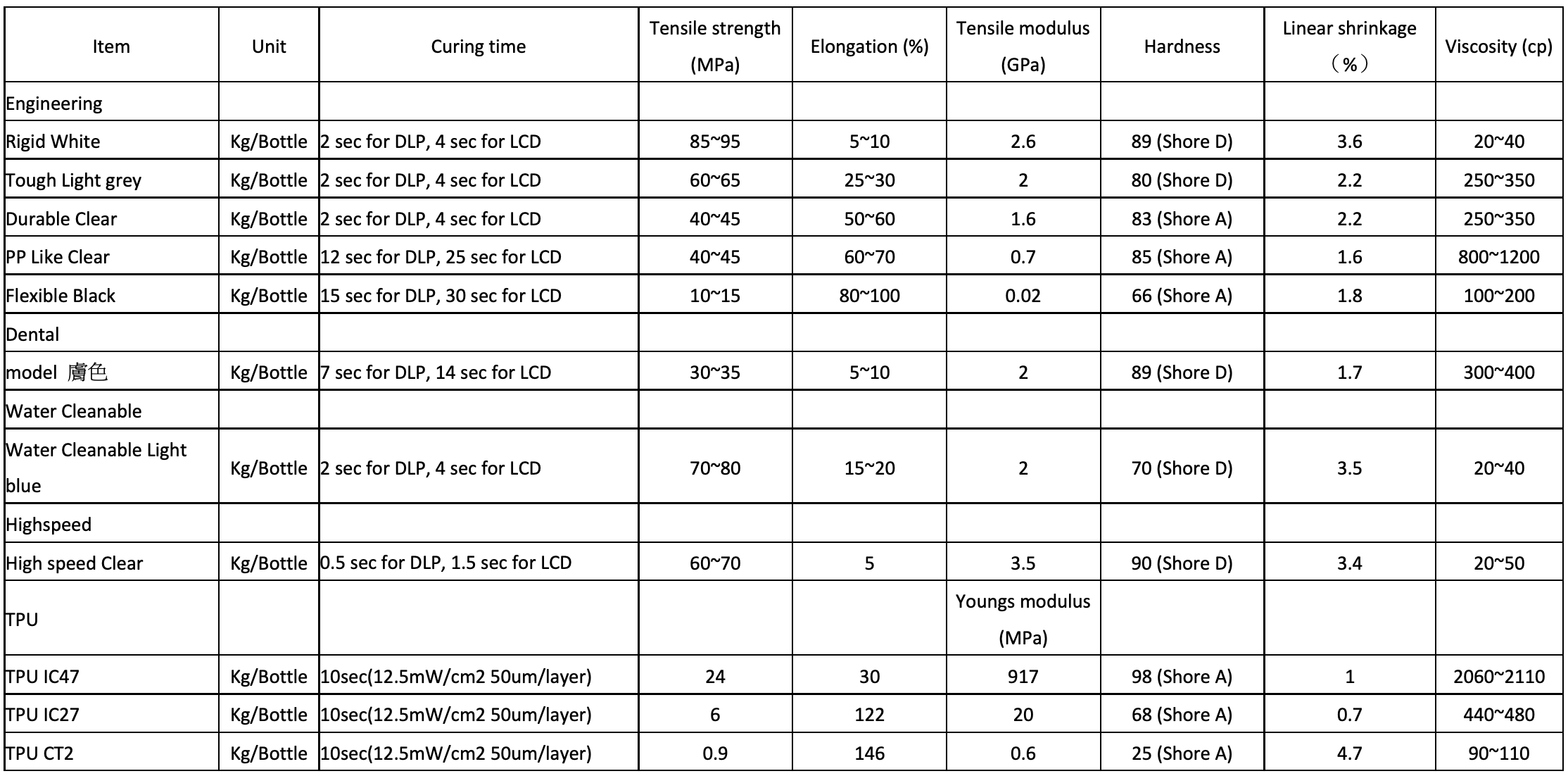

Resin Curing Time and Mechanical Properties

Note.

1. Resin characteristic could be moderate depends on the needs for the market, e.g., making Flexible resin remains its flexibility base in different temperature in each area.

2. Light source power used for the curing time above is DLP:2mW/cm2、LCD:1mW/cm2

3. Curing times for base layer are the time in the chart above times 10.

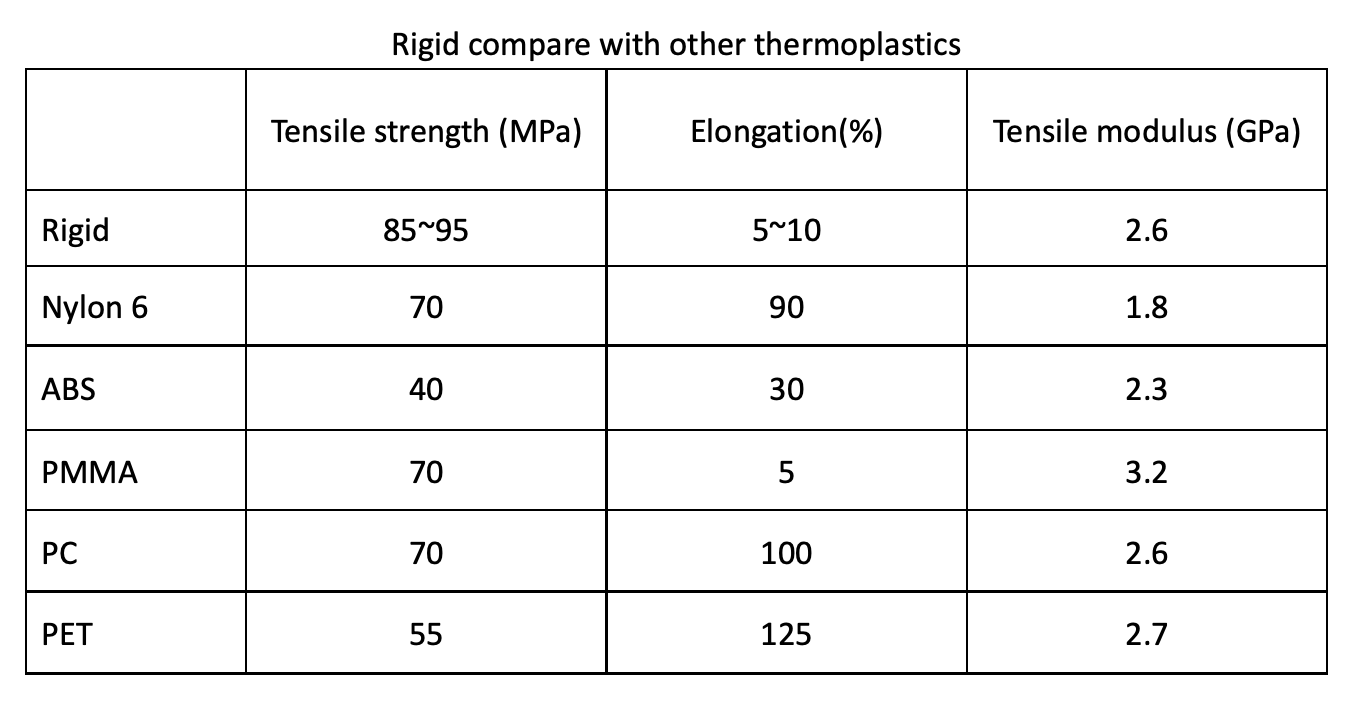

Engineering Resin - Rigid

Characteristic

Glass like texture rigidity and accuracy provide strong deformation resistance. Perfect to print parts with thin wall features.

High tensile strength

Tensile strength could be higher than 90MPa better than most of the thermoplastic. Remain the original mechanical property and won’t be soften and broken at high temperature(150°C)

Application

Turbine, fan, jigs, fixture, valve, manifold, shell for electronics or automobile

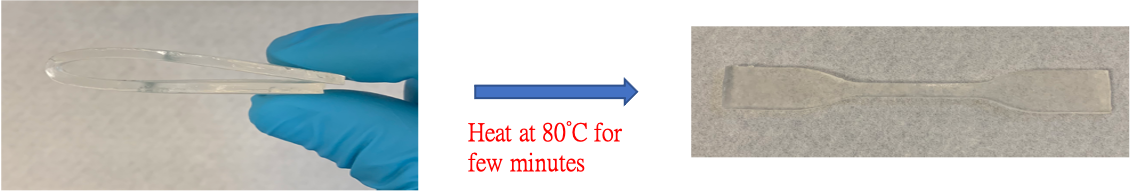

Engineering resin - Tough

Characteristic

ABS like texture with high toughness, stiffness and strong abrasion resistance. Reaching the balance between strength and precision allow the printed part to endure temporary force or deformation. Suitable for functional parts require toughness and stretchiness.

With high toughness and shape-memory, unbreakable under deformation and able to reverse deformation after heated.

Tensile strength is better than ABS

| Tensile strength (MPa)

| Elongation (%)

|

Tough

| 60-65

| 25-30

|

ABS

| 40

| 30

|

Application

High toughness prototype, jigs and fixture, gear, spring, connector, wear resistant and pressure resistant part.