Section:

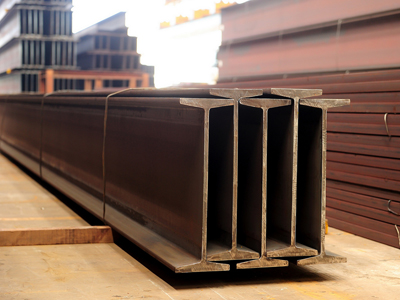

Formed steel is a bar-shaped steel material that has a specific cross-sectional shape and size. The steel billet is heated and undergoes rolling and extension, and is one of the main steel materials used in buildings (steel structures) and other construction projects (bridges, ships, vehicles, and so on). The varieties of formed steel produced by Tung Ho Steel include: H-beams, I-beams, channel beams, and U-beams, among others.

Of these, for H-beams we recommend steel type CNS SN400YB!

After the 1994 Northridge earthquake in California, U.S.A. and the 1995 Great Hanshin earthquake in Japan, it was discovered that steel frame buildings, which was considered as having the best earthquake resistance, were badly damaged or even totally collapsed during the earthquakes (especially for low-rise steel frame buildings), though to a lesser extent than buildings of other frame structures.

After experts and scholars from around the world conducted researches, they found that the chemical components and mechanical properties of the commonly used steels SS400 and A36 were not able to meet the seismic design requirements for buildings. It could even be argued that they were selected solely for their strength, without any considerations of their aseismatic performance. The Japanese government had consequently specified about 20 years ago that the SN steel was the only construction steel that met the seismic design requirements.

However, the Taiwanese steel usage philosophy for low-rise steel frame buildings remains what it was 20 years ago, i.e. use of SS400 and A36. As H-bar steels are the main steels used in the main structure of low-rise steel frame buildings, in 2012, Tung Ho Steel decided to cancel the price raise for H-beam steel made from the SN400YB steel, thereby providing consumers with the SN400YB steel, the only steel that meets the seismic design requirements, at the same price as SS400 and A36, in a bid to accelerate the quality improvement of steels for low-rise steel frame buildings in Taiwan.

Exclusively produced by Tung Ho Steel, 100% sufficient weight

To avoid cross-section coefficient reduction of H-bar steels due to under-thickness tolerance, Tung Ho Steel exclusively produces 100% lumping weight H-bar steels, in order to ensure satisfaction of the strict requirements that the structural strength and cross-section coefficient reach 100% and surpass the CNS national standards. As such, we are well-placed to improve the quality of steel material for buildings in Taiwan and provide consumers with 100% safe and earthquake-resistant H-bar steels used in building frame.

We imprint a lifetime guarantee for consumers on every piece of steel we produce. When you see “THAS” (Tung Ho Accredited Steel) and “CNS SN400YB” imprinted on H-beam steel, this is the mark of Tung Ho Steel’s guarantee that the steel truly complies with the highest safety standards for earthquake resistance.

Download

Hot Rolled H-Beam

H-beam steel has a strong ability to resist bending, and the parallel nature of its two wing surfaces make connection, processing, and installation easy and convenient. Moreover, under identical cross-section surface loads, hot-rolled H-beam steel structures are 15%–20% lighter than traditional steel structures and can be processed into T-beams and castellated beams through combinations of molded cross-sections to satisfy the needs of project design and production.

These are broadly applied in large-scale buildings with major load-bearing capabilities and stable cross-section performance, as well as in bridges, ships, cranes, equipment foundations, support frames, and foundation piles. Demand is growing by the day.

Checkered H-Beam

Utilizing the hot-rolling method of integrated molding to imprint the outer side of the wing plate with a checkerboard pattern, the surface pattern depth design gives the product good resistance against wear and good resistance against slipping. It is suitable for cover plates involving applications in temporary steel bridges, rapid transit, and other civil engineering projects.

I-Beam

The method that uses materials most efficiently under identical load-bearing conditions with easy, convenient, and rapid construction that can be completed by a single person. Moreover, prior to each type of I-beam steel being shipped from the factory, it undergoes hot-dipped galvanizing treatment to prevent corrosion. The products are able to bear impacts and heavy weights, and good ventilation reduces impacts from wind damage.

Broadly applied in industrial buildings and metal structures such as factories, bridges, ships, agricultural vehicle manufacturing, and power transmission towers

Channel

Channel beams, a type of carbon structural steel for use in construction and machinery, are a complex cross-sectional formed steel material whose cross-section is in the shape of a channel. It is a material commonly used in industrial production and is often welded to various parts as a support that strengthens the structure. Currently, Tung Ho Steel primarily produces large-scale channel steel that is manufactured domestically without human labor. Wing plate tapered channel beams (CB) are primarily produced for the Taiwanese market, while wing plates and other parallel flange channels (PFC) are primarily focused on outside market sales.

Widely applied in building structure and vehicle production, as well as other industrial structures. Often used in conjunction with I-beam steel.

1. Wing plates and other parallel flange channels (PFC): Because the wing plate cross-sectional area is increased, the channel steel cross-section modulus is improved. Therefore, these can provide greater cost-effectiveness compared to wing plate tapered channel beams.

2. Wing plate tapered channel beams: The channel steel wing plate is made of a tapered channel steel characterized by a thick interior that gradually thins out toward the exterior. When connecting, construction is relatively inconvenient.

U-type sheet piles

Tung Ho Steel has formed a technical research and development team at the Miaoli Works to actively research and develop steel sheet pile products. Many resources have been employed in the team’s work, and in June of 2014 successful product development was achieved. This product is now officially on the market. Since Tung Ho Steel began production, domestic U-beam steel sheet pile supply is no longer reliant on foreign sources. In future, more domestic infrastructure projects will benefit from U-beam steel sheet piles characterized by high strength, light weight, good waterproofing, durability, and easy of construction.

Broadly used in retaining walls, piers, dams and levees, and other projects. Moreover, it can be recycled and reused, with evident effects of protecting the environment.

- GL (Germanischer Lloyd)

- NK (Nippon KaijiKyokai,ClassNK)

- (BV) Bureau Veritas of Shipping

- DNV (Det Norske Veritas) – Approval of Manufacturer Certificate

- ABS (American Bureau Of Shipping)

- LR (LR of Shipping)

- CE MARK FOR LRV

- LR FPC (Certificate of Conformity of Factory Production Control)

- ACRS (Australasian Certification Authority for Reinforcing and Structural Steels Ltd)

- MIT (Made in Taiwan) Smile Logo

- CNS Mark

- JIS Mark (Japanese Industrial Standard)