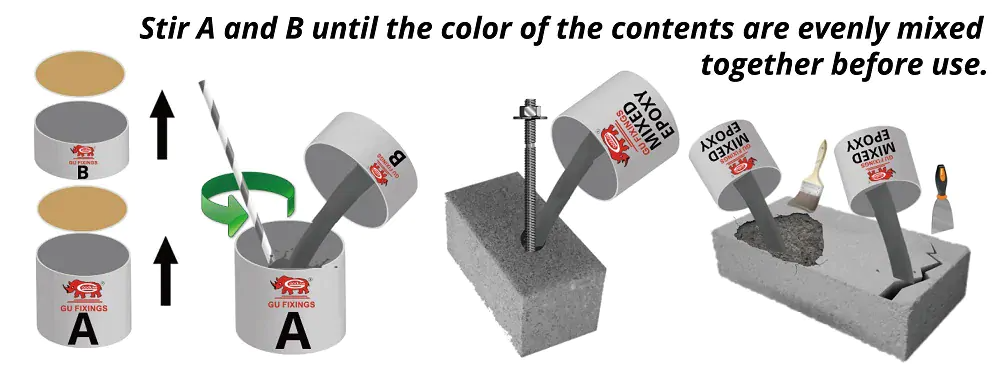

Installation

1. The hardener is poured into the container of the resin and then fully mix the 2 components until the mortar is the same color throughout.

After throughout mixing, the mortar has a high bond strength to building materials.

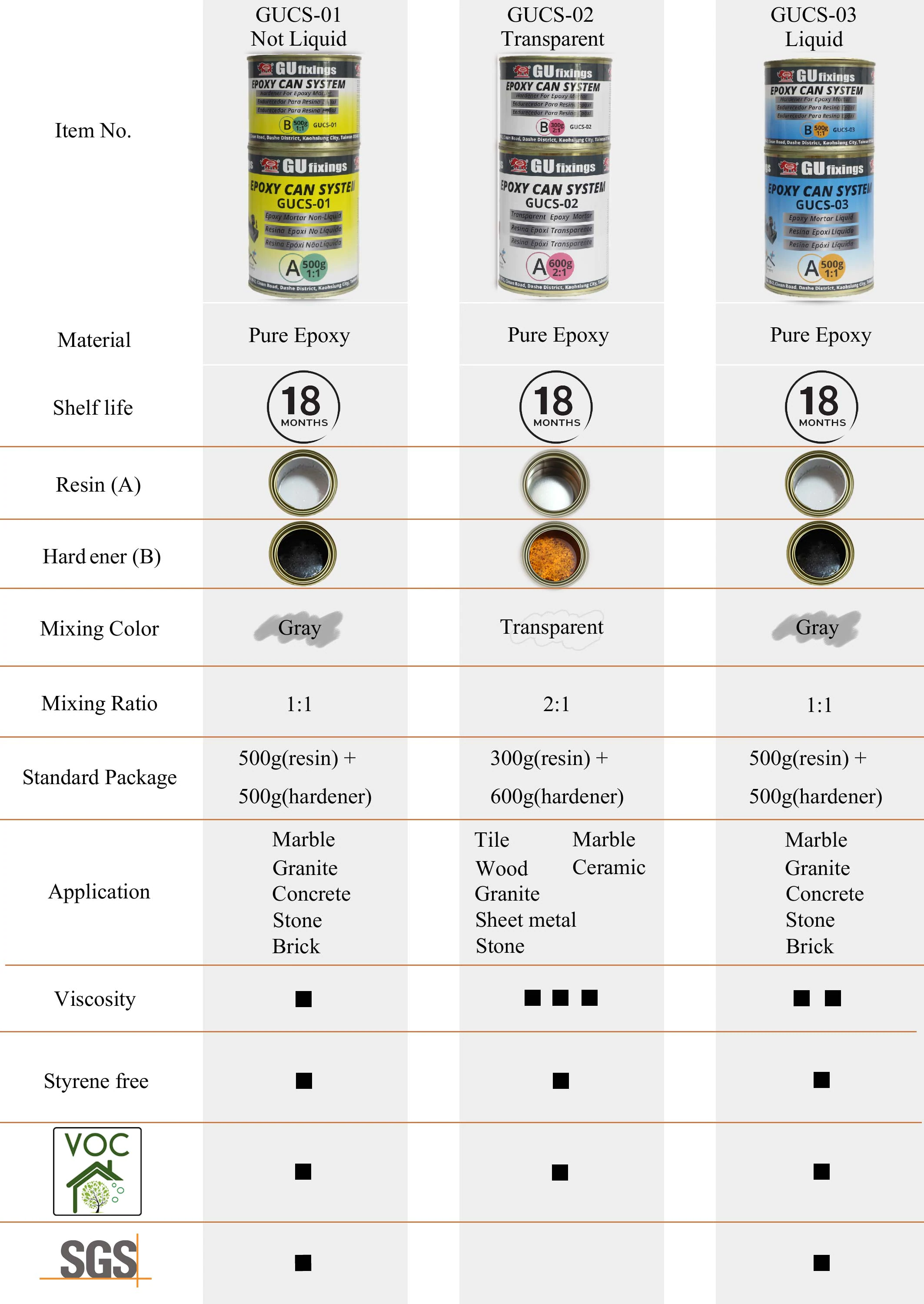

2. Can System Mortar have 3 versions:

- GUCS-01 is suitable for using in horizontal situation and on walls or ceilings.

- GUCS-02 is clean epoxy, high performance in compressive and tensile strength, suitable for wooden construction, especially in hard to reach areas.

- GUCS-03 is liquid, can be poured into vertical holes or cracks or gaps, or used with a brush. Can System Mortar present high strength in 24 hours (20℃) after mixing throughout.

3. Stored in a cool, dry, ventilated place, out of the reach of children, away from heat sources.

4. The mixing quality of the 2 components and the correct filling of the holes or cracks or gaps (without air pockets) will effect the load-bearing capacity.

5. Surface must be clean, porous, free from dust or grease.

Packaging:

1. 500g(resin) + 500g(hardener) in cans

2. Resin: White

3. Hardener: Black

3. Good Use Label or no Label.

4. EXP Date on the top of can.

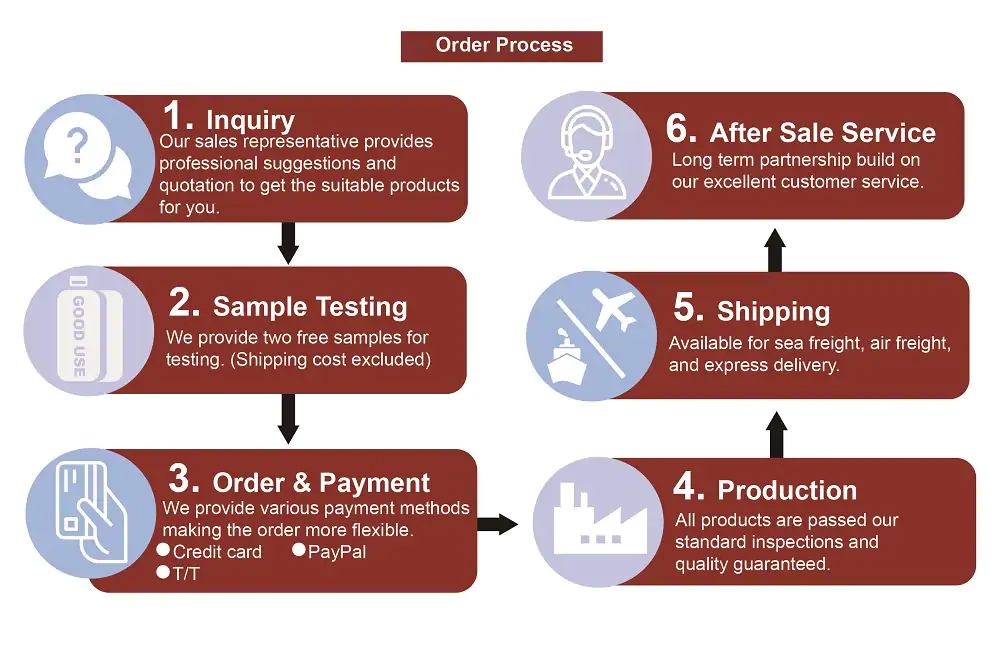

Shipping:

Shipping:

1. Shipments can be arranged by sea, air, courier express.

2. Courier express includes GDA, DHL, Fedex, TNT, UPS, EMS, SF, etc.