Automatic check weigher

PID:

1772765

Model No:

0

Made in:

Taiwan

Quantity:

1000 Piece(s)Available

-

+

Payment:

Send Inquiry

Supplier Details

HANDWIN PRECISION IND. CO., LTD

Member Since

2015

Address

No.482, Sec. 3, Taihe Rd., Changhua City, Changhua County 500, Taiwan (R.O.C.)

+886-4-7375879

Contact Seller

View company information >

Key Features

• Automatic zero tracking technology ensures the weighing accuracy under the condition that the weight of the product changes on the weighing platform.

. Maintaining consistent level of accuracy over long-term use.

. Maintaining consistent level of accuracy over long-term use.

• Using high-rigidity, high-sensitivity weight sensor reduces vibration stabilization time, and equipped with high-speed CPU processor for high-accuracy weighing results.

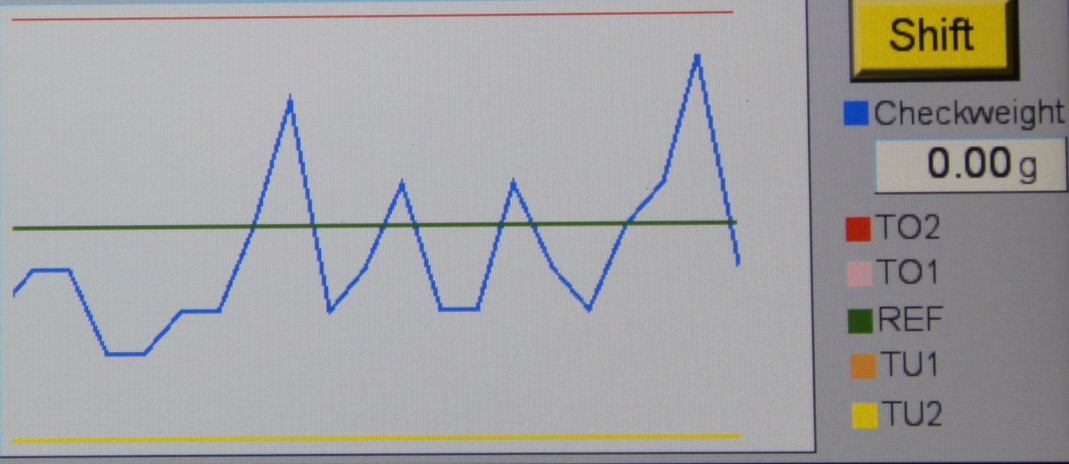

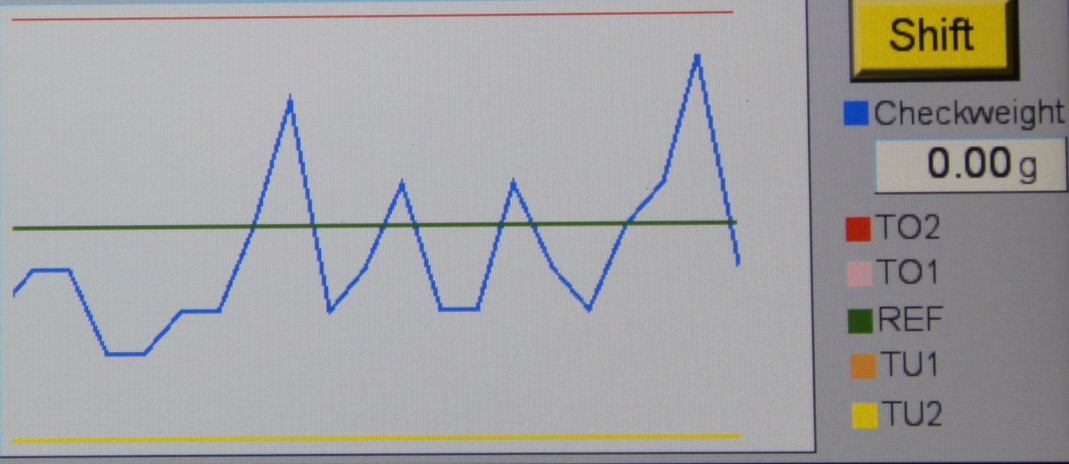

•10.1 inch color TFT LCD display Full color touch screen, easy to view, easy to understand, easy to operate, prevent operator error.

• Input product lenght (mm) and throughput (pcs/min), calculates immediately by the exclusive automatic parameter calculation function.

05.The most complete production management system

•. Product database stores up to 199 products . Instant display of weight upper and lower limit graph. . Summary graph includes histograms, and pie charts, can be converted to Excel file . Checkweighting parameters can be copied between products. . Create backup of product parameters and system parameters, in case of need.

. Divided into four levels, administrator, engineer, supervisor, and operator. . Add or remove users under each level. . Password protection prevents unauthorized access and change of parameter . Access rights are custom made for each level, avoid violating other user's rights.

. Stores checkweighing history data in machine interface or usb drive . Machine interface can store 2.3M piece of checkweighing data.

•System will automatically record the user login time and parameter modification.

. Capable of communicating with external devices, providing intelligent industry 4.0 . Modbus RTU/TCP communication protocol for seamlessly integration. . Communication port includes RS-232, RS-485, ethernet, USB 2.0 . Built-in free agreement, select any of the communication items.

.Follow three steps according to the figure to complete the calibration procedure. .Operation is simple, fast and accurate.

•Many languages to choose from , English, Simplified Chinese, Traditional Chinese, ... .Interface language can be changed to accommodate customer needs.

•.Immediate notification when system self-detects a fault for instant processing.

•Immediate notification when system self-detects a fault for instant processing.

•

.Full stainless (SUS304) machine body, with brushed finish. .Electricial cabinet with internal hinge, cable tracks. .Conveyor platform with quick release

•.Food and medical grade belt, easy to clean and maintain. .Ultra-thin, seamless bonding, stable operation at high speed.

.

Attachment

Video