Polycarbonate Ti-Lite ROMA Metallic Green Sheet

| Profile | ROMA (76/18) Medium Circular Corrugated |

| Base Material | Clariant UV and Light Stabilizers Co-Extruded |

| UV Protection | Clariant UV and Light Stabilizers Co-Extruded |

| Ti-Lite Technology | Exceptional Shade and Heat Reduction properties |

| Heat Reduction Properties | Lowers Temperatures up to 15 degrees celsius |

| Color | Metallic Green |

| Warranty | 10 Year Limited Warranty |

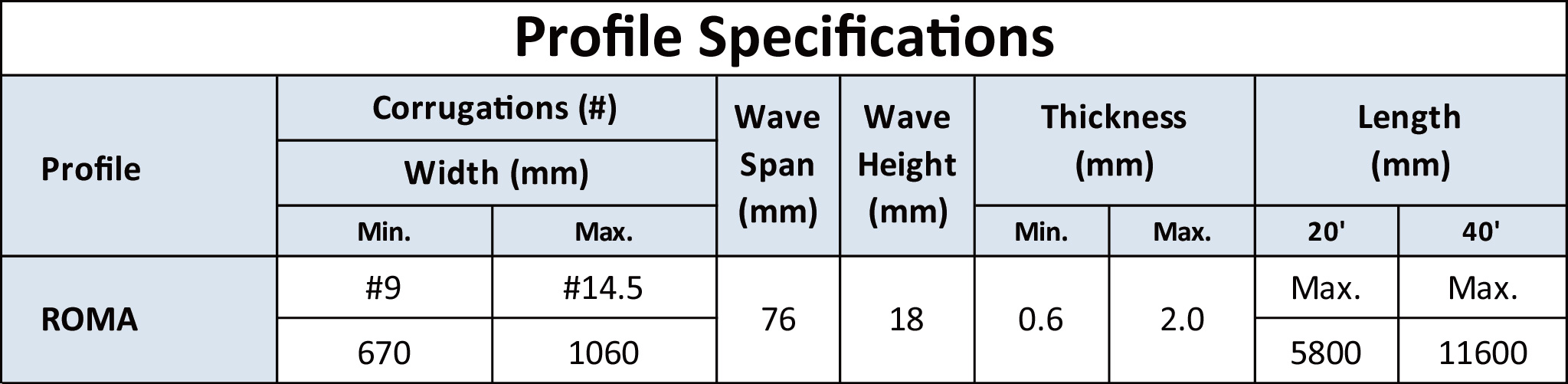

| Thickness | 0.6mm~2.0mm |

| Width | 670mm (9 Corrugations) ~ 1060mm (14.5 Corrugations) |

| Length | Customizable - Cut to Length |

As we know, polycarbonate is the clearest of all plastic resins. How do we add shading and heat reduction properties effectively? Coloring is clearly not the best solution.

At VULCAN Plastics we developed Ti-Lite; a material developed specifically to cope with the blazing sun, adding extra shade and heat reduction properties to the otherwise clear PC sheet. . The result is a product with excellent shading properties combined with glare reduction, with an average of 46% visible light transmission rate (depending on the color), exceptional heat blocking capabilities - temperature drop of 7°c~15°c depending on the setup.

- Profile: Polycarbonate ROMA (76/18) Medium Circular Corrugated

- Raw Material: 100% Virgin Covestro UV Stabilised resin.

- UV Coating: Clariant UV and Light Stabilizers

- Ti-Lite Technology: Exceptional Shade and Heat Reduction material

- Color: Metallic Silver

- Thickness: 0.6mm~2.0mm

- Width: 670mm (9 Corrugations) ~ 1060mm (14.5 Corrugations)

- Length: 2440mm, 3660mm, 4880mm, 5800mm, 5900mm, 9000mm, 10000mm, 11000mm, 11600mm (other sizes can be cut to length upon request)

- Warranty: 10 Year Limited Warranty

- 100% Virgin UV included raw material ensures that your sheets can withstand harmful UV rays for at least one year.

- Co-Extrusion ensures evenly spread, evenly thick base material and UV coating.

- Clariant UV and Light stabilizer co-extruded coating as used on lenses, glasses, and sunglasses. 99.5% of harmful UV wavelengths between 290nm~400nm are blocked.

- This layer of coating is crucial to proctecting the sheet itself, and what is underneath.

- Excellent shading properties, on average 46% light transmission rate (Reduced VIS – 380~780nm).

- Exceptional heat reduction properties (Controlled NIR – 780~2500nm), temperature drop of 7°c~15°c depending on the relative temperature and humidity.

- Aesthetically pleasing from the outside, and provides sufficient lighting with no glare indoors.

- 250 times the impact strength over glass and 10 times over FRP and Acrylic.

- Polycarbonate sheets produced with 100% Virgin material have a melting point of at least 190 degrees Celsius and produce only odorless smoke when burned.

- VULCAN Polycarbonate sheets can be tailored with different coatings to provide different light transmission rates and properties.